Ejectors

Subcategories

-

Single-stage

NOVACOM's SINGLE-STAGE EJECTORS RANGE

Our single-stage ejectors (VM, in line, and VT/ VT VA) are designed to be as compact and light as possible to facilitate their merging into your systems.

Our anti-clogging range is highly recommended in polluted environments (dust, powders, etc.). With his "in-line" range design, the impurities generated by the atmosphere will not block the nozzle. This helps maintain optimal performances.

Available in Aluminium 6082 or Stainless Steel 316L, it will withstand extreme environments.BENEFITS

Our single-stage ejectors are simple, reliable and economical. They create an independent and confined vacuum, close to the suction cups.

For more information, contact us. -

Multi-stage

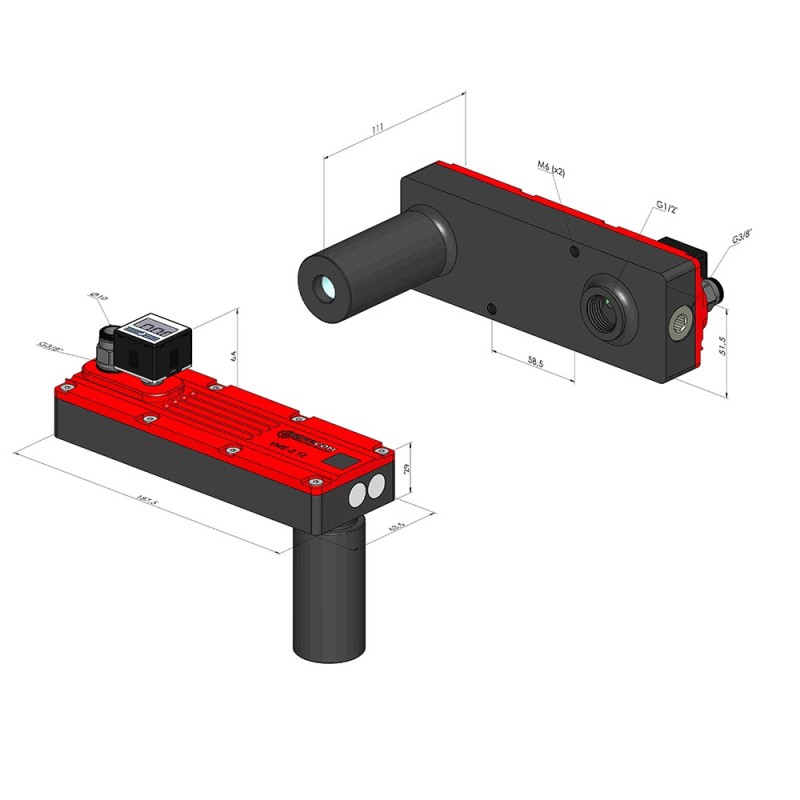

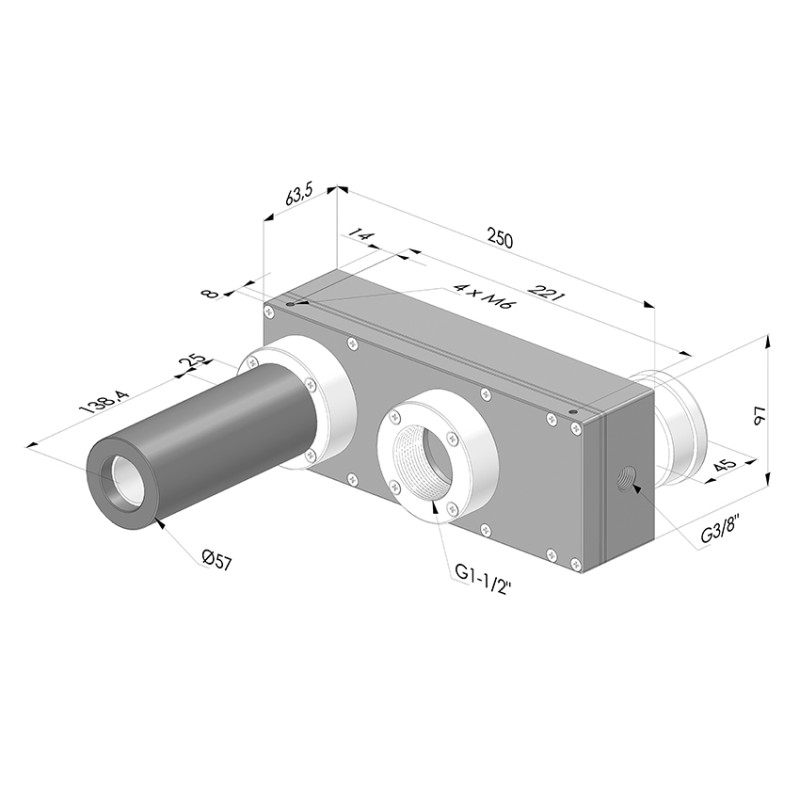

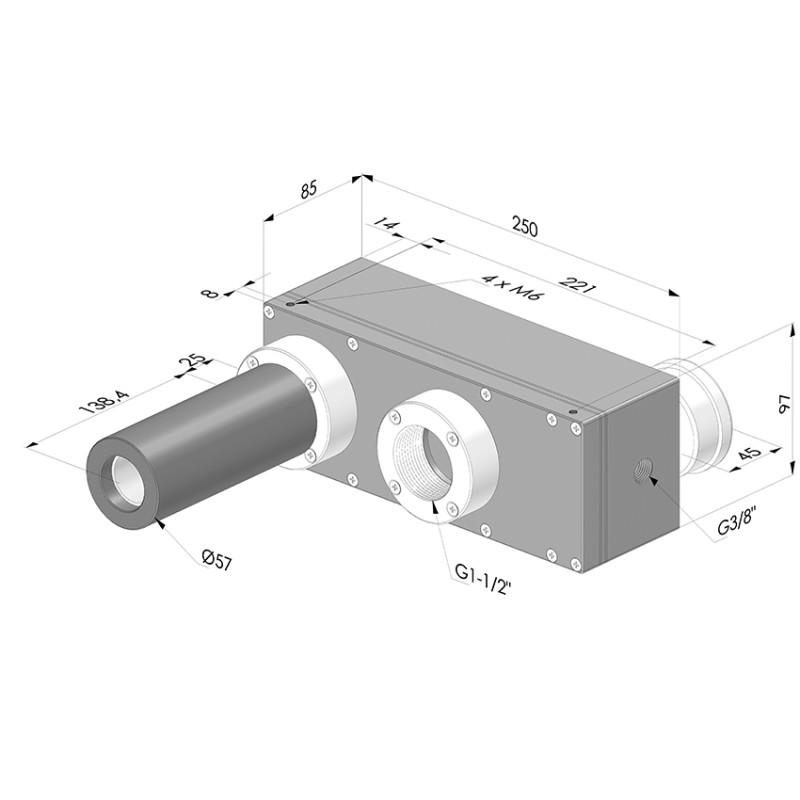

NOVACOM's MULTI-STAGE EJECTORS RANGE

Our multi-stage ejectors (VME-1 series, VME-2 series) operate on the same principle as our single-stage ejectors, but they're set in series in the same body or box. This allows a large volume of air to be sucked in.

We have integrated multi-stage cartridge technology into our ejectors, which provides better performance compared to a single-stage ejector.

The Grip series (1 multi-stage cartridge) can be installed as close as possible to the suction cups, on a machine or even on a custom made vacuum box.

Our PVP (from 2 to 12 multi-stage cartridges) allow the suction of a large volume of air with a very short response time.BENEFTIS

- Very high suction flow as soon as it is put under compressed air

- Very short response time

- Low noise level -

Vacuum Box

The vacuum box with NOVACOM foam band, CVM CS series is a system for gripping objects of varying weights and sizes in industrial sectors.

Equipped with a venturi system with back-blowing, the vacuum chambers are used in the field of packaging, order preparation, palletization, de-palletization or even the change of conveying line.

The flexible and waterproof handling foam allows the grip of specific, irregular or porous surfaces such as wood, plastic, cardboard, metal, brick, tiles and many others...

-

Feed Ejectors

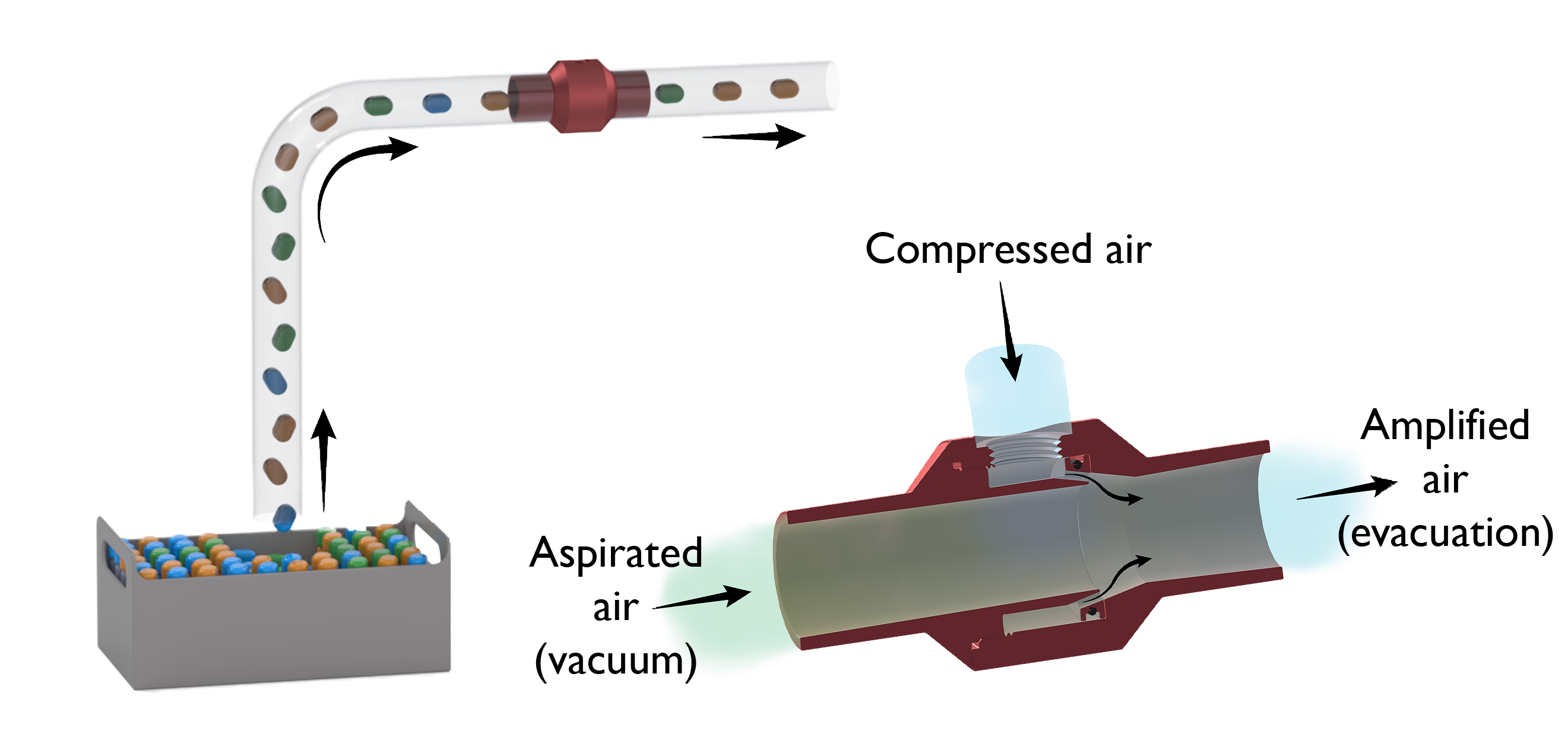

OPERATING PRINCIPAL

Our TP Series Ejectors allow the suction and transfer of various materials (powders, granules, steel balls, wood chips, etc.) and it can also be used in smoke extraction.

These transportation ejectors are available in aluminium or stainless steel with output sizes ranging from 19 mm to 152 mm.

The maximum transport length is determined by the density of the product and the arrangement of the installation (elbow, etc.). For long distances transportation, it is recommended to install the TP ejectors in series.

BENEFITS

- Instant on/off

- No maintenance

- Explosion proof

- Economical

- Space-saving

OPERATING PRINCIPAL

-

Suction Tubes

-

Air Guns

DESCRIPTION

NOVACOM's pneumatic airguns can suction or blow without any electrical supply or moving parts, using only compressed air. It is ideal to suction any types of debris, that will be directly gathered in a cloth bag. It is also possible to use it to transfer materials from a tube to a container (PP90). By simply reversing the valve, the pneumatic air gun is switched to a blowing mode and can blow out a consequent air flow with low pressure and air consumption.

BENEFITS

- Shock resistant

- Easy to use

- No maintenance

- Lightweight and portable

- Economical

- Safe, no need to use electricity

OPERATING PRINCIPAL

By reversing the nozzle, the pneumatic gun switches from the suction function to the blowing function.

APPLICATIONS

- Vacuuming chips, dust, ceramics, sawdust, filings, etc.

- Transfer of pellets and small parts

- Blowing waste, water and other liquids

-

Vacuum Barrel Pump

DESCRIPTION

The VACUUM BARREL PUMP 90 F series uses the venturi principle to suction liquids by vacuum. The pump is connected to the first bung of the metal drum, and the transfer hose is screwed onto the second and connected to a dip tube. Simply connect the pump to a compressed air supply source and open the air intake valve. By creating a vacuum inside the barrel, the pump creates a suction. Likewise, by a simple pressure reversal, it will be possible to empty the barrel of its contents. This system works using compressed air. It is adjusted and tested with a maximum safety pressure which will not exceed 2.5 bar in the barrel for a supply pressure of 2 bar. This function is guaranteed by a valve inside the device.BENEFITS

- No electricity, no moving parts

- Excellent performance

- No contact of the pump with the product

- No deterioration or wear of the system even with a high concentration of metal shavings

OPERATING PRINCIPAL

Operating principal of a vacuum barrel pump

APPLICATIONS

- Evacuation and transfer of liquids, sludge, loaded soluble oils, chips on lathes, bar turning machines, milling machines, grinding machines, machining centers, tanks and other machines

TECHNICAL INFORMATION

For more information, contact usDetails Barrel Pump 200 Liters Max operating pressure 2,5 bar Recommended working pressure 2 bar -

Accessories

-

Ejectors instructions

NOVACOM proposes a large product range of ejectors, adapted to a lot of industrial applications and production processes, answering to all industrial requirements. These vacuum generators are also called venture nozzles or vacuum pumps. We distinguish the following models: single stage, multi stage, anti-obstruction, pneumatic conveyance. The selection of the right ejector is carried out in function of the required flow rate, respectively the desired suction capacity. The uses of our ejectors can be very different: mounting in a switchboard or a working machine, direct fixing to the suction cup for a local and precise vacuum, compact integration in the robotic, deployment in dusty working environment, high cycle times, and great volumes of drawn air… [id_lpsflipbook=85] [id_lpsflipbook=86] Instructions VM SERIE Instructions VM SERIE [id_lpsflipbook=87] [id_lpsflipbook=89] Instructions VCR-2 Instructions VCR-2 EV [id_lpsflipbook=90] [id_lpsflipbook=91] InstructionsVMK Instructions VML [id_lpsflipbook=92] [id_lpsflipbook=93] Instructions VMT Instructions VT - [id_lpsflipbook=94] [id_lpsflipbook=95] Instructions VT VA Instructions GRIP 30 [id_lpsflipbook=96] [id_lpsflipbook=97] Instructions PVP 2 Instructions PVP 4 [id_lpsflipbook=98] [id_lpsflipbook=99] Instructions PVP 6 Instructions VME 1 [id_lpsflipbook=100] [id_lpsflipbook=101] Instructions VME 1 Instructions counter blowing 130x300 [id_lpsflipbook=102] [id_lpsflipbook=103] Instructions counter blowing 130x400 Instructions counter blowing 130x600 [id_lpsflipbook=104] [id_lpsflipbook=105] Instructions counter blowing 130x800 Instructions counter blowing 130x1000 [id_lpsflipbook=106] [id_lpsflipbook=107] Instructions counter blowing 130x1200 Instructions With balls feelers 130x300 [id_lpsflipbook=108] [id_lpsflipbook=109] Instructions With balls feelers 130x400 Instructions With balls feelers 130x600 [id_lpsflipbook=110] [id_lpsflipbook=111] Instructions With balls feelers 130x800 Instructions With balls feelers 130x1000 [id_lpsflipbook=112] [id_lpsflipbook=113] Instructions With balls feelers 130x1200 Instructions Without ejectors 130x300> [id_lpsflipbook=114] [id_lpsflipbook=115] Instructions Without ejectors 130x400 Instructions Without ejectors 130x600 [id_lpsflipbook=116] [id_lpsflipbook=117] Instructions Without ejectors 130x800 Instructions Without ejectors 130x1000 [id_lpsflipbook=118] [id_lpsflipbook=119] Instructions Without ejectors 130x1200 Instructions Feed ejectors TP 19 [id_lpsflipbook=120] [id_lpsflipbook=121] Instructions Feed ejectors TP 25-51 Instructions Feed ejectors TP 76-152 [id_lpsflipbook=122] [id_lpsflipbook=123] Instructions Suction tubes Instructions Air Gun Series PP24 [id_lpsflipbook=124] [id_lpsflipbook=125] Instructions Air Gun Series PP90 Instructions Vacuum Barrel Pump Series POMPE 90

Italian

Italian French

French