DETECTABLE SUCTION CUPS

PERFORMANCE IN SENSITIVE ENVIRONMENTS

At NOVACOM, we have rethought vacuum gripping to meet the challenges of the most demanding environments. Discover our range of detectable material suction cups, designed for optimal detection, minimizing contamination risks in the food, pharmaceutical, and other sensitive industries.

THE ADVANTAGES OF DETECTABLE SUCTION CUPS

Maximum safety in sensitive environments

In the food and pharmaceutical sectors, where contamination is a major concern, NOVACOM’s detectable suction cups are ideal. They are specifically designed to be detected by control equipment, preventing unwanted fragments from compromising product quality. These suction cups stand out not only for their ease of detection but also for their resistance to cleaning agents and disinfectants, ensuring impeccable hygiene throughout the production process.

Rigorous selection for enhanced performance

We know that choosing the ideal suction cup depends on many criteria. That is why we support you in selecting the product suited to the weight, temperature, material, and surface of the objects you need to handle. NOVACOM offers you numerous references to meet each specific need.

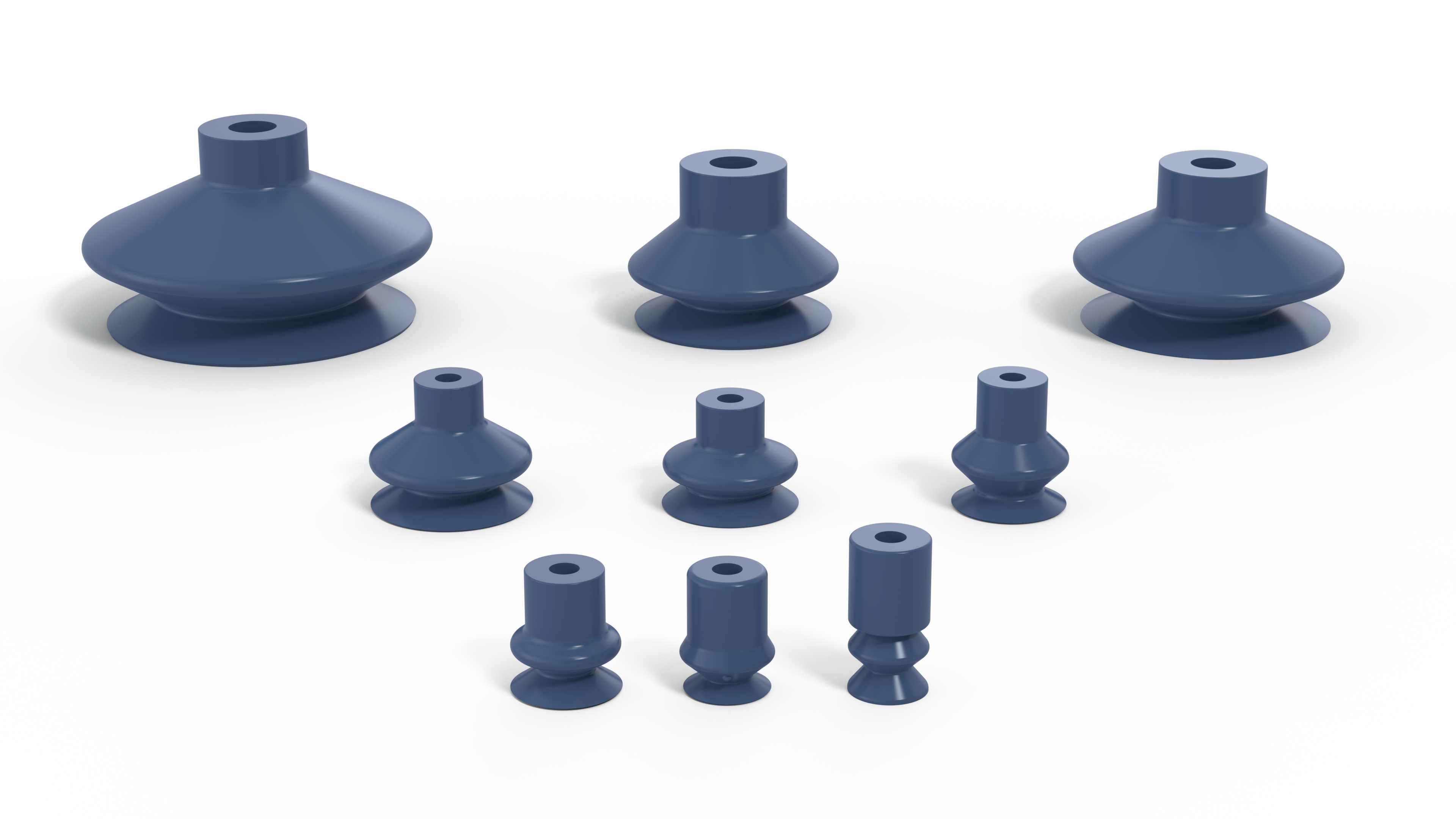

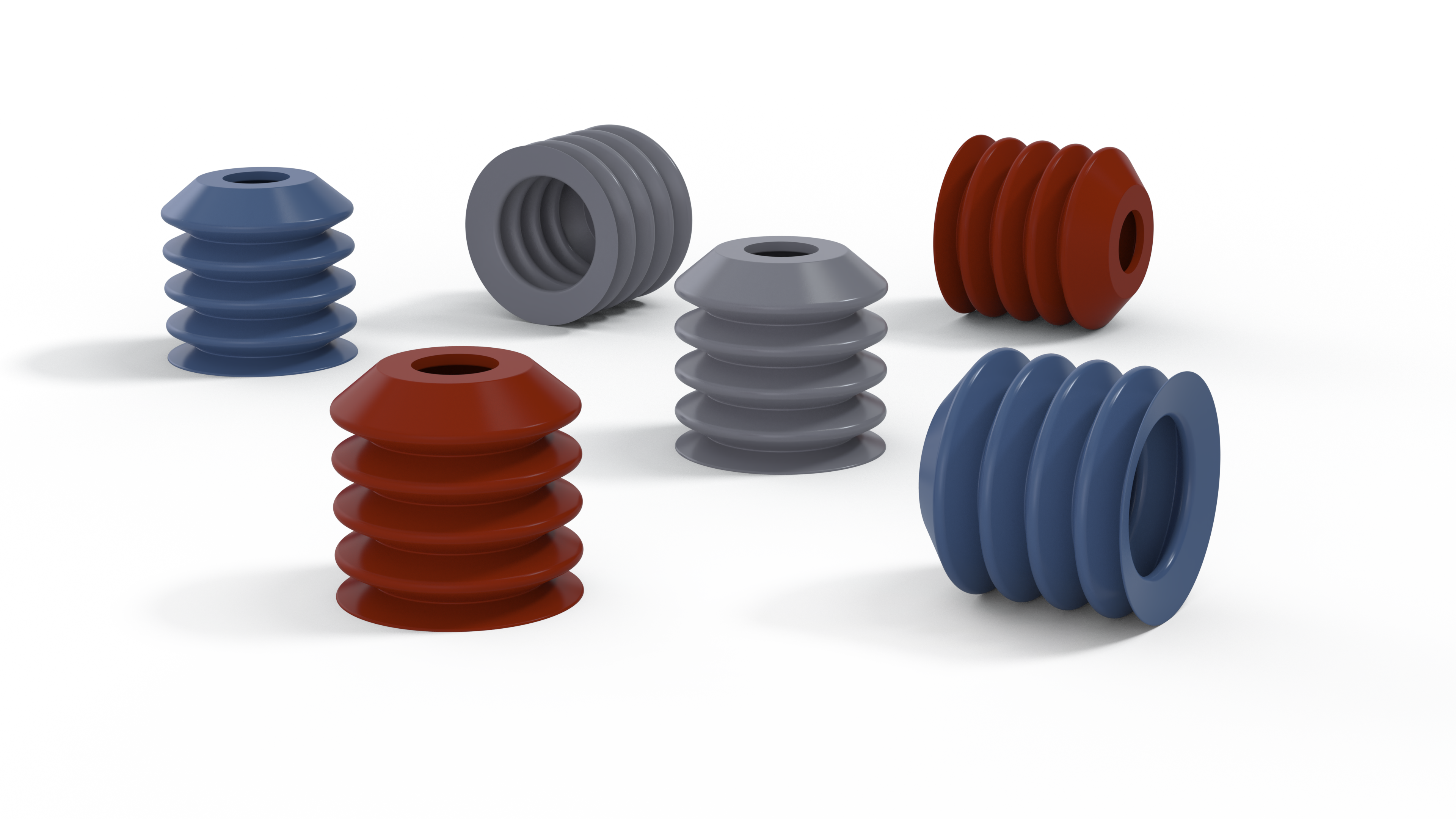

A visual signature for food safety

Our detectable suction cups feature a distinctive blue tint for immediate visual identification. This color, rarely found in natural ingredients and processed foods, is chosen to contrast with the majority of food products. In the event of accidental deterioration, any suction cup fragment is easily detectable visually.

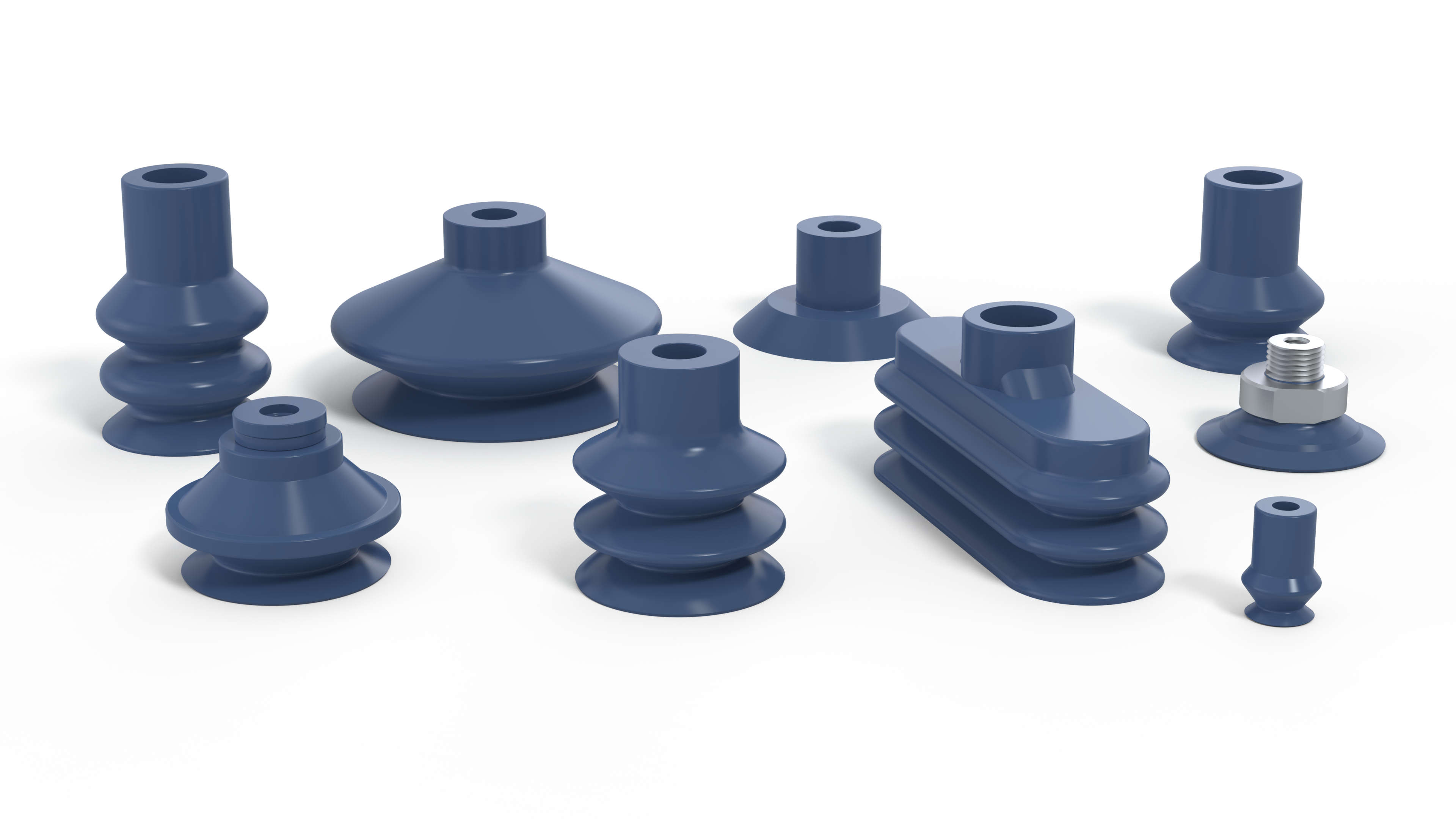

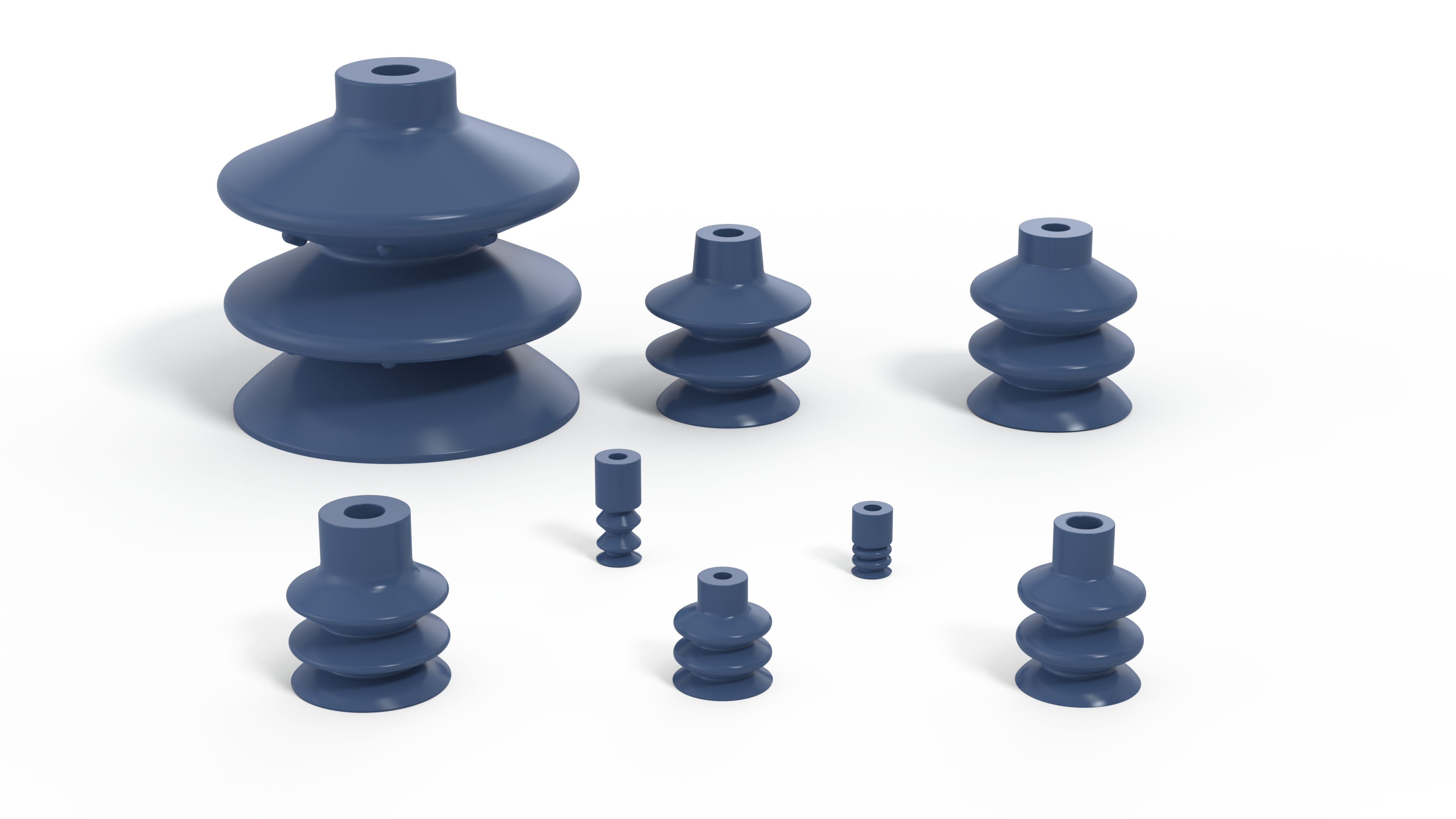

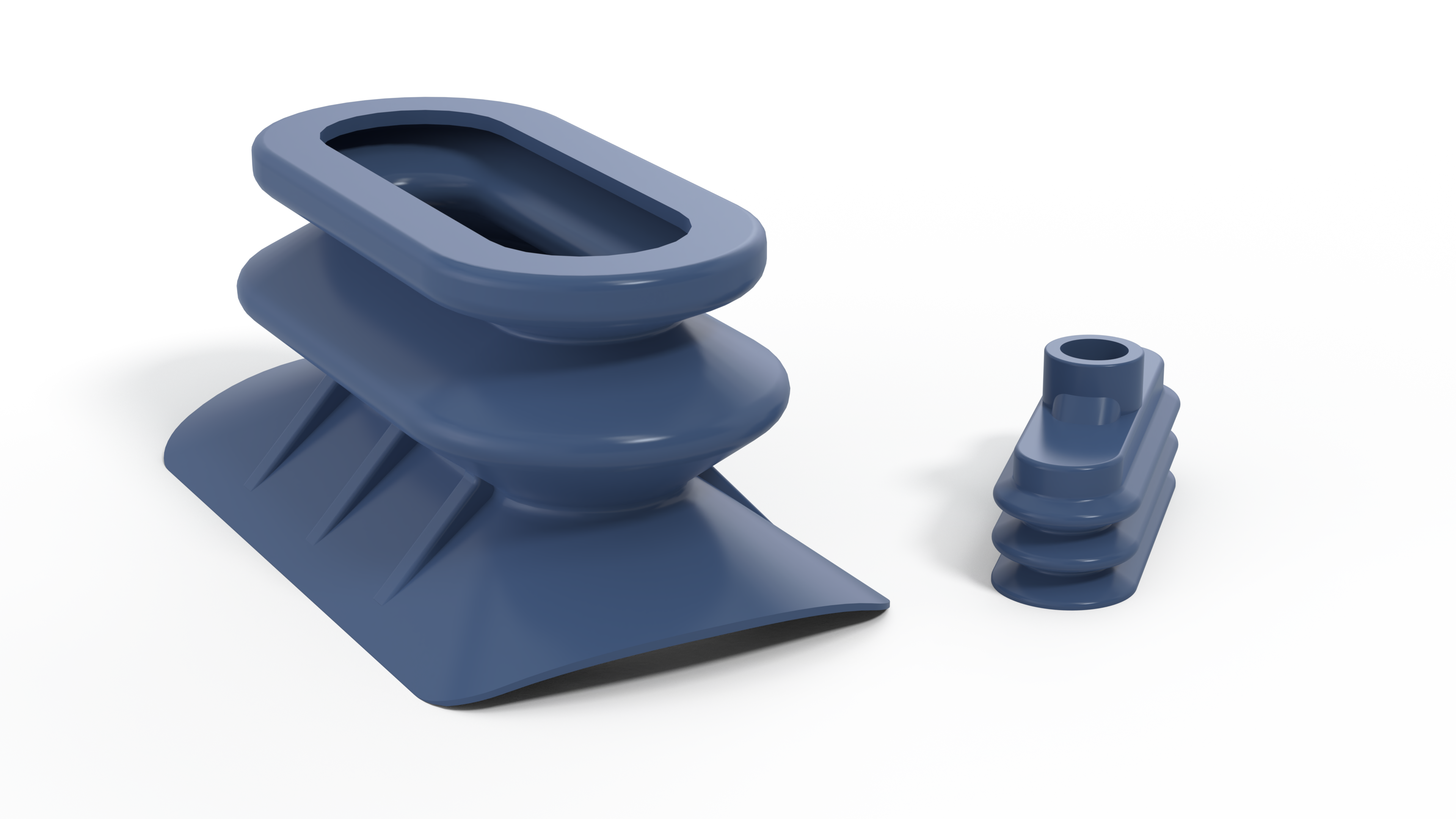

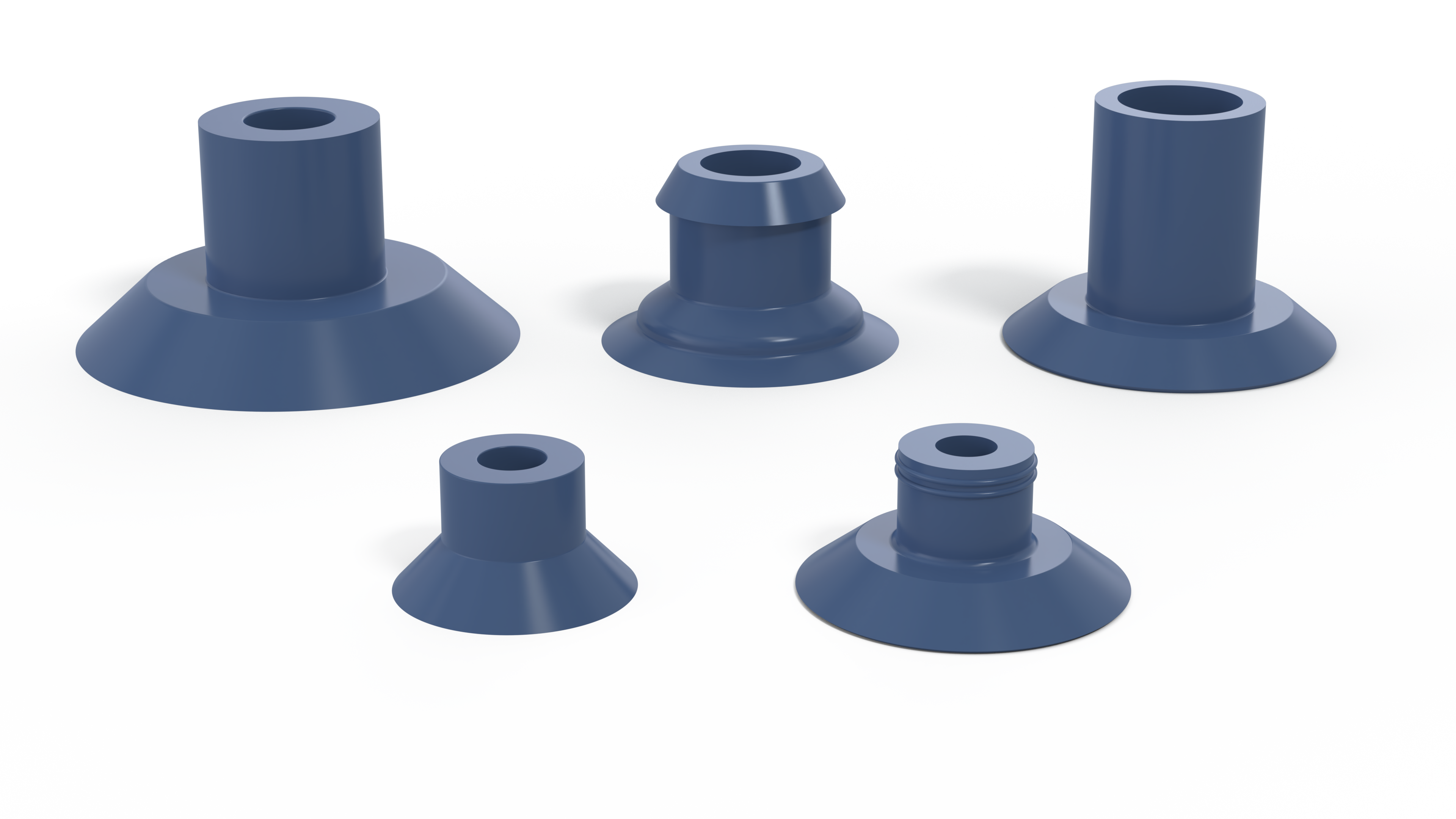

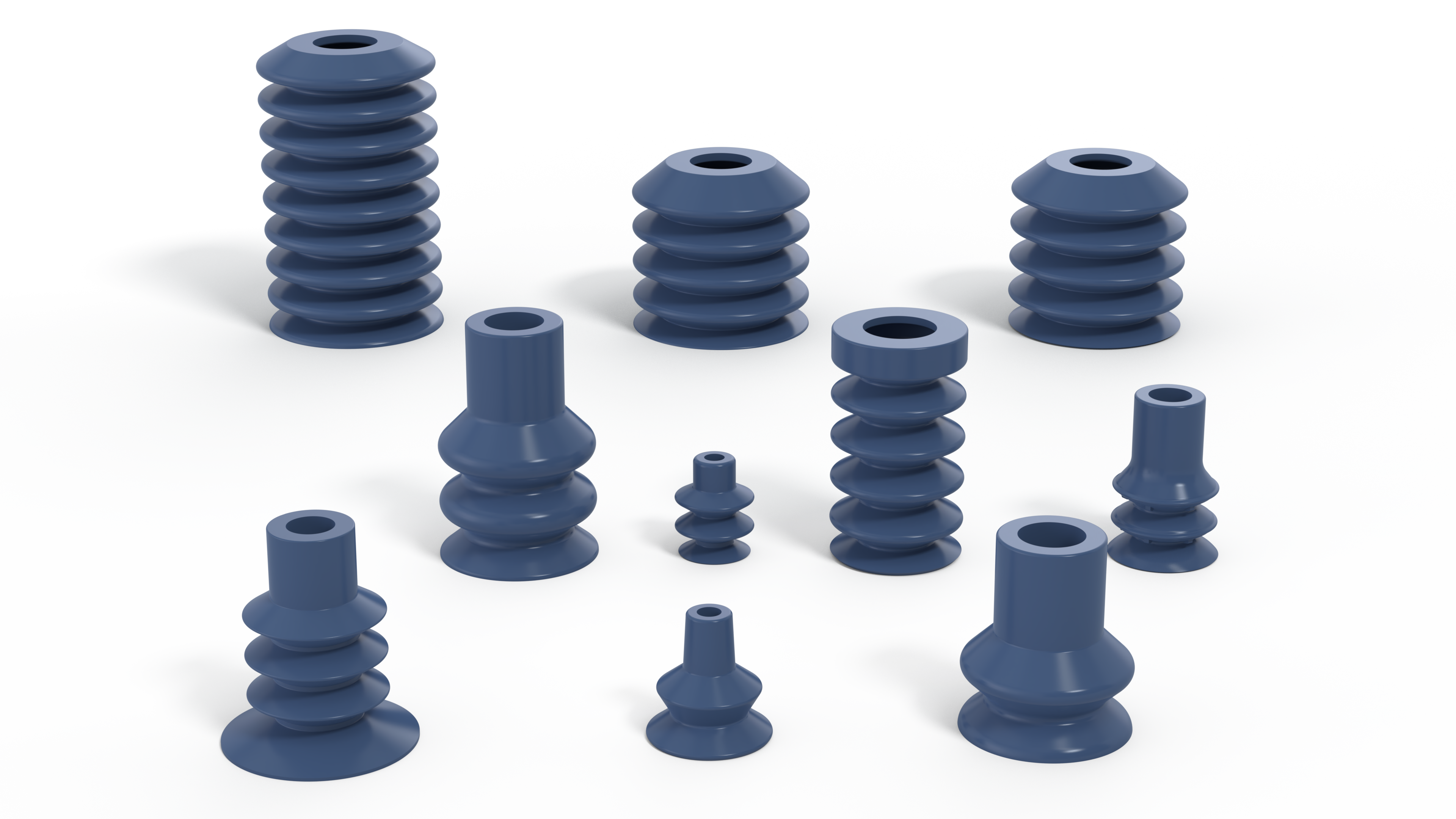

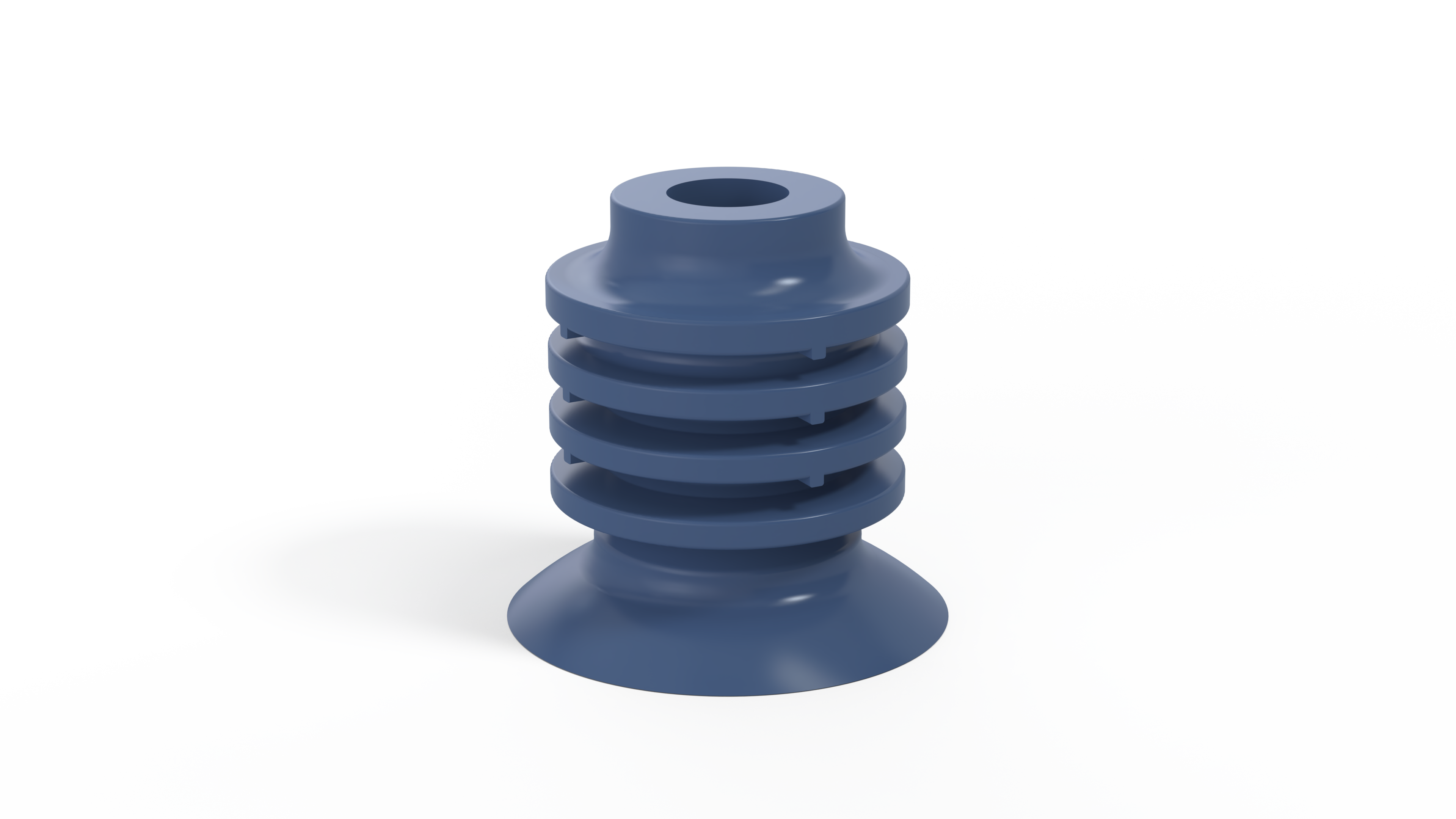

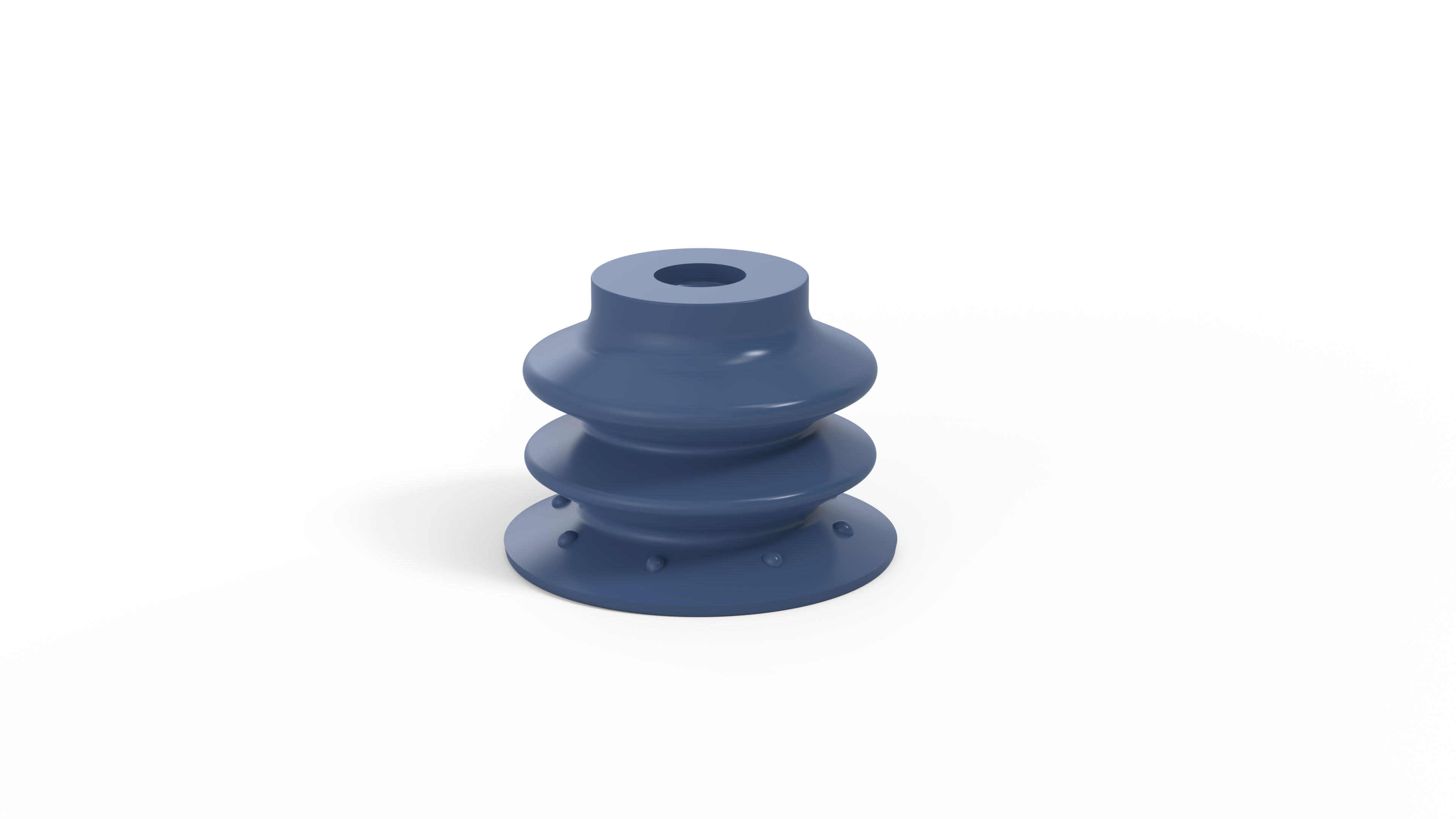

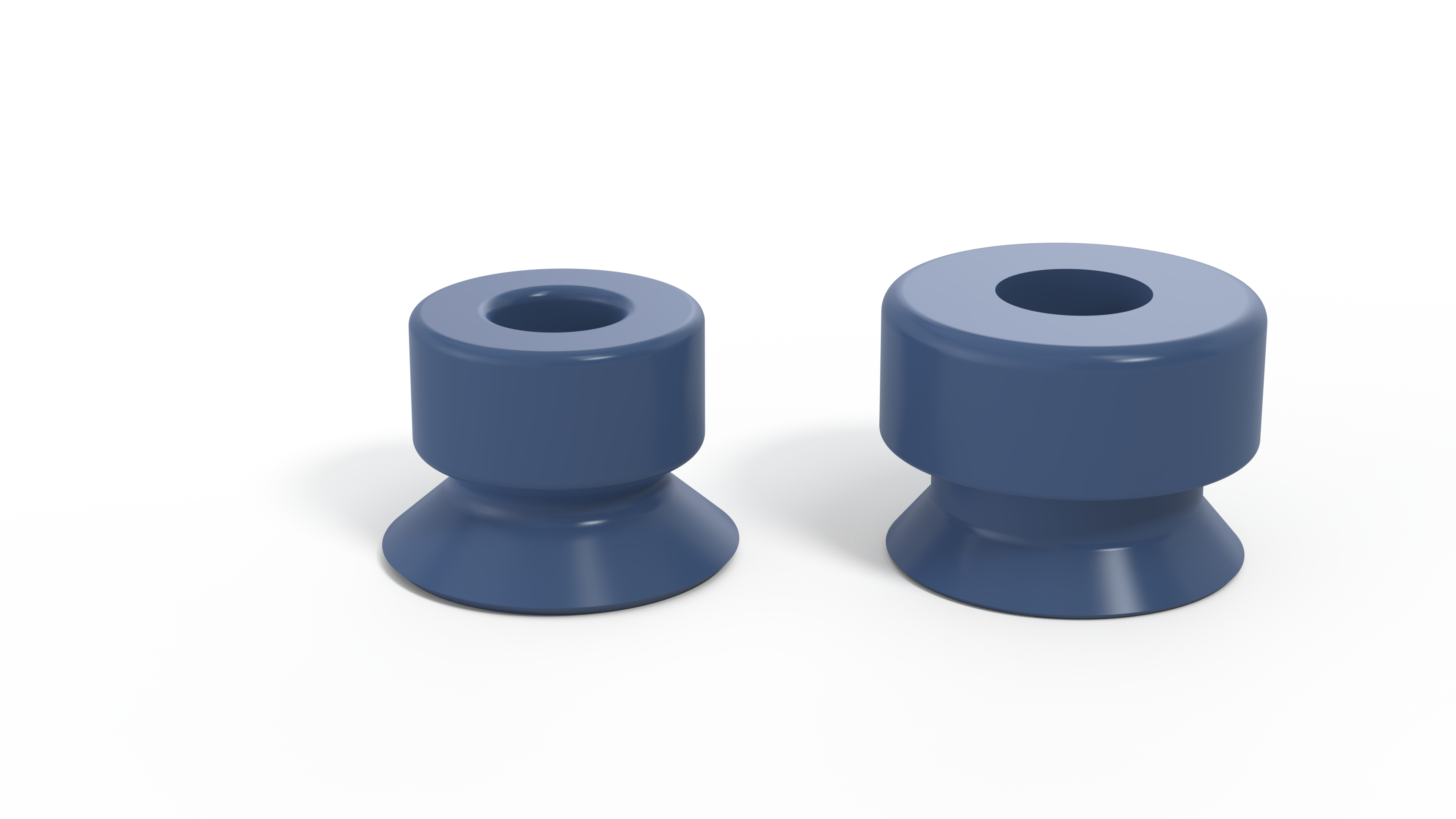

THE SUCTION CUP RANGES

Our range of detectable suction cups comes in various shapes: flat, bellows, oblong, rectangular, to perfectly fit every application. Regardless of the shape or surface of your parts, our suction cups ensure safe and efficient handling, even in challenging conditions.

| IMAGE | PRODUCT DESCRIPTION | CUSTOMER REFERENCE |

|---|---|---|

|

Series 1 1.5 bellows suction cup Ø10mm to Ø52mm Shore 40/60 |

1 11SLDB A 1 14SLDB A 1 20SLDB A 1 23SLDB A 1 33SLDB A SH60 1 53SLDB A 1 53SLDB A SH60 |

|

Series 2 2.5 bellows suction cup Ø10mm to Ø85,8mm Shore 40/60 |

2 11SLDB A SH60 2 20SLDB A SH60 2 26SLDB A SH60 2 31SLDBLEU A 2 12SLB A |

|

Series 4PA - 4VS Oblong suction cup 65x25mm to 118x54mm Shore 40/60 |

4PA118 54 31SLDB A 4PA65 25 32SLDB A 4VS 75SLDB A SPF12 |

|

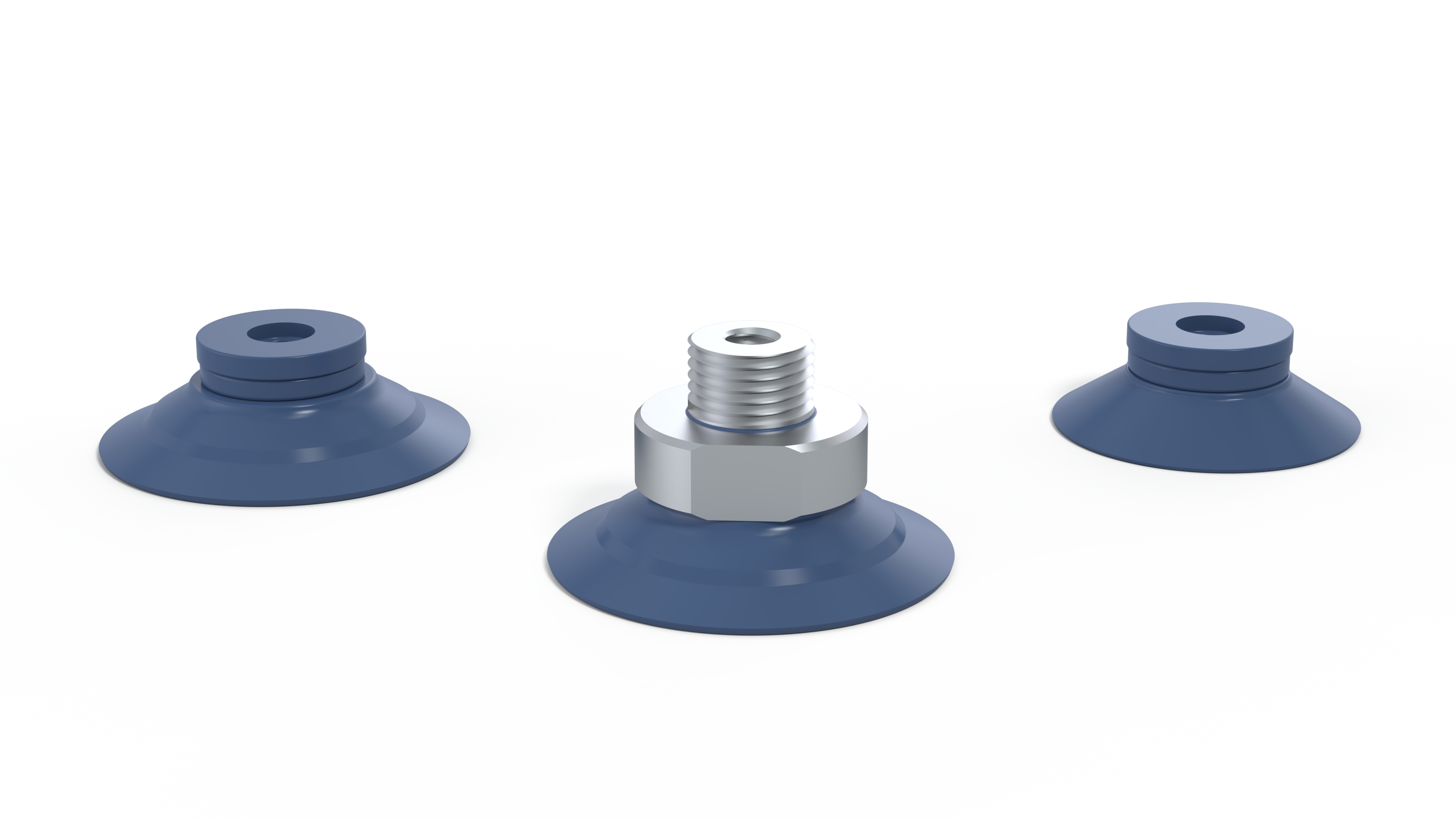

Series 7 Flat suction cup Ø24,5mm to Ø40mm Shore 40/60 |

7 40SLDB A 70S 20SLDB A SH60 71 27SLDB A |

|

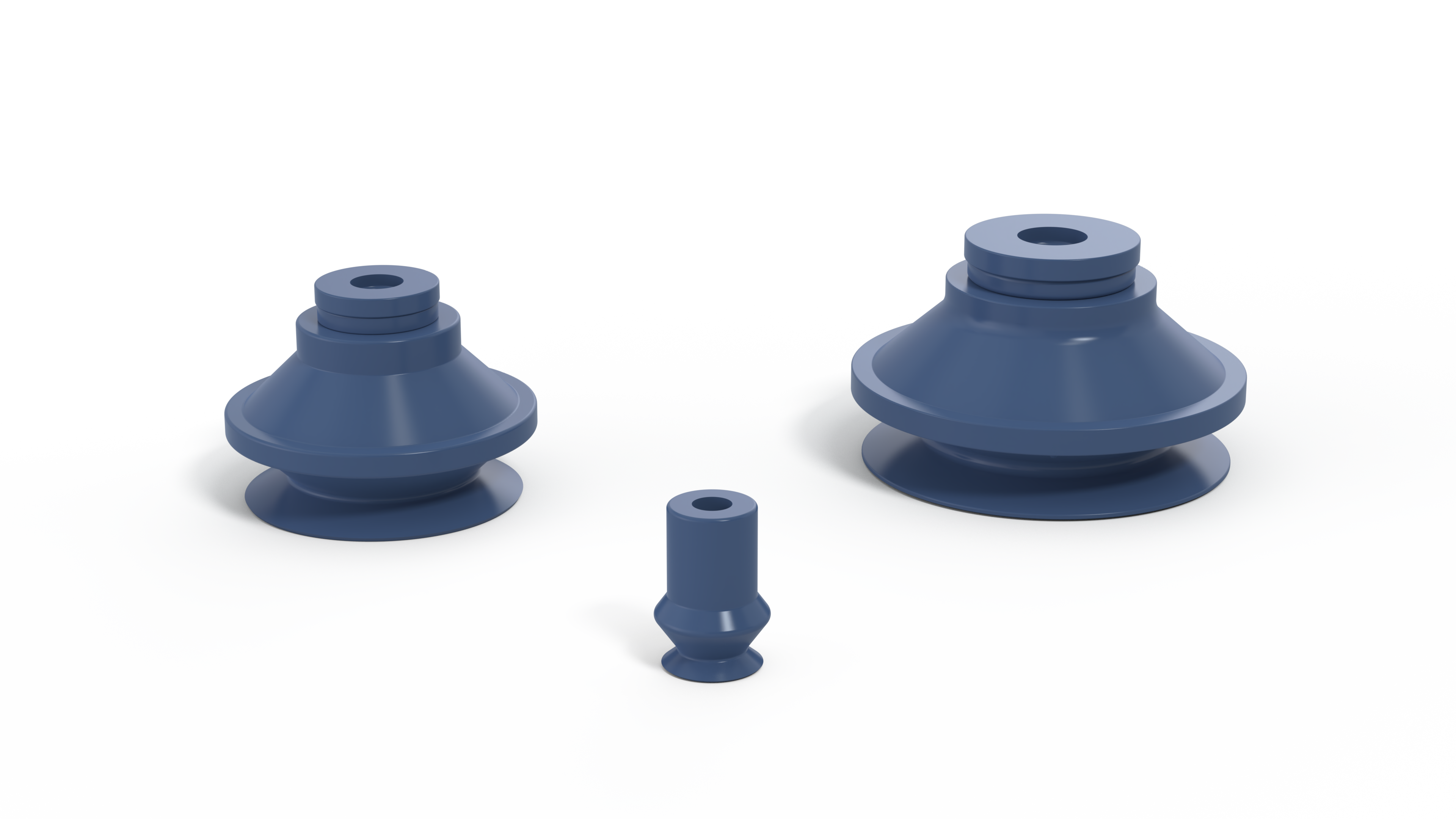

Series 8 and 8K Ø13,5mm to Ø49,8mm Shore 40 |

8 14SLDB A 81 40SLDB A 81 40SLDB A SH60 82 40SLDB A 82L 40SLDB A 88A 30SLDB A 8K 45SLDB A 8K 50SLDB A |

|

Series 90 Flat suction cup Ø27mm to Ø31,8mmm Shore 40 |

90 25SLDB A 90 30SLDB A |

|

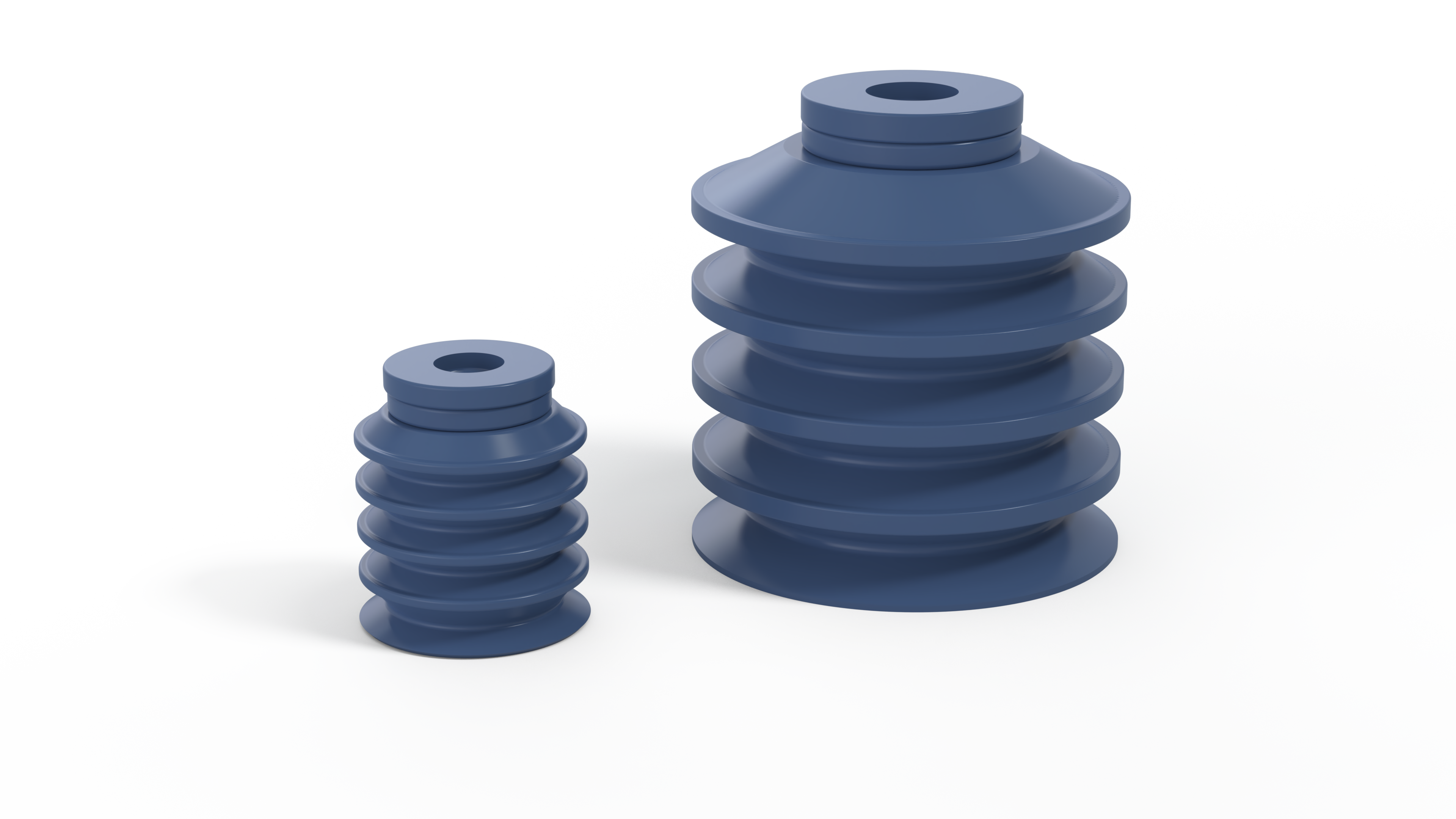

Series 91 1.5 bellows suction cup Ø10,2mm to Ø43,5mm Shore 60 |

91 20SLDB A SH60 91 31SLDBASH60 |

|

Series 92 4.5 bellows suction cup Ø20mm to Ø39,5mm Shore 40/60 |

92 20SLDB A 92 20SLDB A SH60 92 40SLDB A SH60 92 30 SLB A |

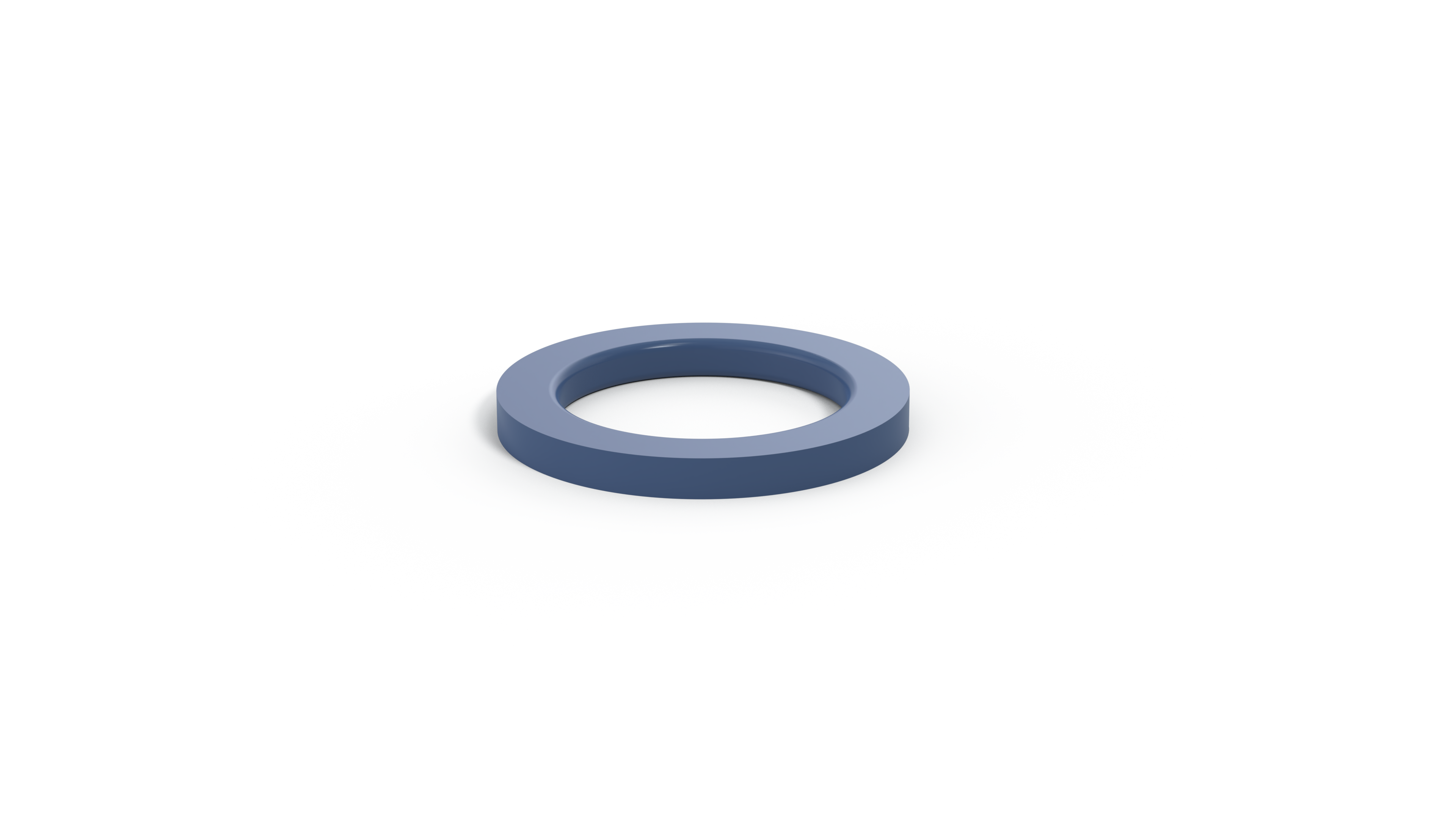

|

Reinforcement ring for series 90 / 91 / 92 Øext 20mm Øint 14mm Shore 40/60 |

BAG 9P18SLB BAG 9M18SLDB SH60 |

|

Series 95 4.5 bellows suction cup Ø41mm Shore 40 |

95-2 40SLDB A |

|

Series 96 2.5 bellows suction cup Ø41mm Shore 40 |

96 35SLDB A SH60 |

|

Series PFG Flat suction cup Ø10mm Shore 40 |

PFG 10ASLDB A |

DETECTABLE SILICONE [SLD]

TEMPERATURE RESISTANCE:

-60°C TO 250°C

PRODUCT MATERIAL :

Our silicone rubber with a metal-detectable additive features a composite formulation resistant from -60°C to 250°C with high flexibility and significant UV resistance.

It is available in blue, red, and grey, and in different Shore hardness levels: 25, 40, and 60.

APPLICATIONS :

These materials are primarily used in the pharmaceutical and food industries.

| Code | Material | Color | Standard Shore Hardness (+/- 5) | Flexibility | Abrasion Resistance | Temperature Resistance C° | UV / Weather Resistance | Oil Resistance | Food Compatibility |

|---|---|---|---|---|---|---|---|---|---|

| SLDB | Detectable Silicone * | 40 or 60 | +++ | - | -60/+250 | +++ | - |   ** ** |

|

| SLDR | Detectable Silicone * | 25 or 40 | +++ | - | -60/+250 | +++ | - |   ** ** |

|

| SLDG | Detectable Silicone * | 40 or 60 | +++ | - | -60/+250 | +++ | - |   ** ** |

|

+++ Excellent ++ Good + Low - Poor -- Not recommended

* Possibility to request FDA and/or CE certification for various references upon order, please contact us.

** Food contact certification: (CE) 1935/2004 - (FDA) 21 CFR § 177.2600

FDA CERTIFICATION : ● ● ●

All products used in the silicone compound for the above-mentioned type are on the FDA 21 § 177-2600 positive list.

CE CERTIFICATION: ● ● ●

All products used in the silicone compound of the referenced parts comply with the requirements of EC Directive 1935/2004 Article 3 and are in accordance with the decree of November 1992.

ROHS CERTIFICATION : ●

All compounds used comply with European Directive 2011/65/EU and its amendments (restriction of lead, mercury, cadmium, chromium, PBB, and PBDE).

All compounds used comply with European Delegated Directive 2015/863, which officially adds the following 4 new substances and their maximum concentration values in homogeneous materials to Annex II of the RoHS Directive 2011/65/EU and its amendments.

RESPONSES TO SIMULANTS FOR DETECTABLE BLUE SILICONE SH40: ● (A, B and D2)

Migration tests verify that silicone suction cups do not release harmful substances into the handled products. They simulate real-use conditions by testing substances like oil or water. If the results meet the standards, the suction cups are compliant. If not, adjustments are necessary. These tests ensure product safety according to European standards.

| FOODSTUFFS CONCERNED | SIMULANTS TO BE USED |

|---|---|

| All types of foodstuffs | A,B,D2 |

| All types of foodstuffs, except acidic foodstuffs | A,D2 |

| All types of aqueous, acidic, and alcoholic foodstuffs and all dairy products | B |

| All types of aqueous and acidic foodstuffs and alcoholic foodstuffs up to 20% | A,D2 |

Italian

Italian French

French