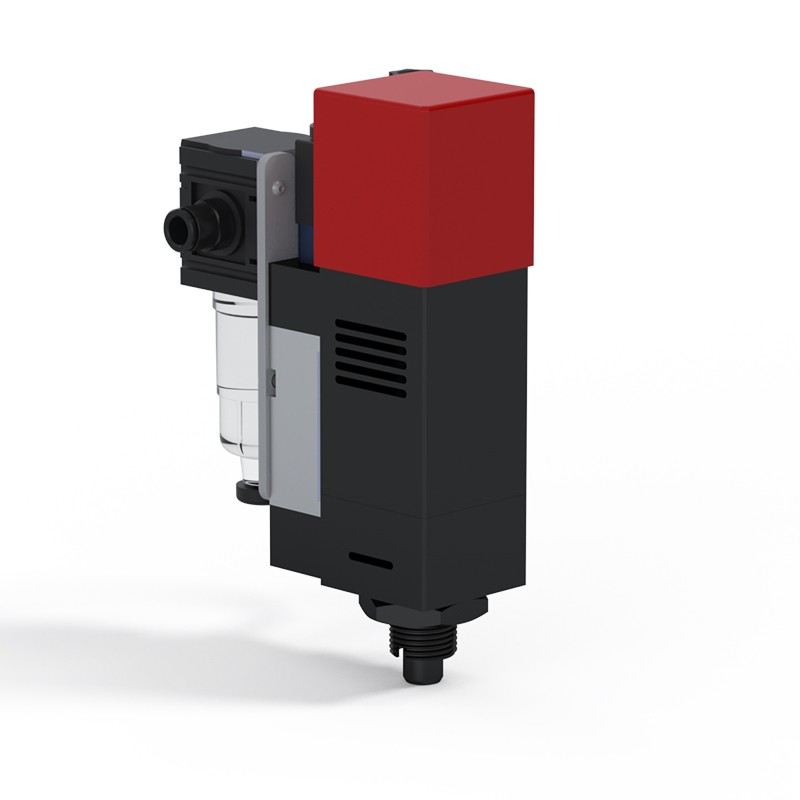

| Material | Anodised Aluminium |

|---|---|

| Type | cabinet cooler |

| Consumption | 400 to 990 Nl/mm |

| Capacity | 95 to 720 Kcal |

| Weight (g) | 1085 |

TECHNICAL DATA

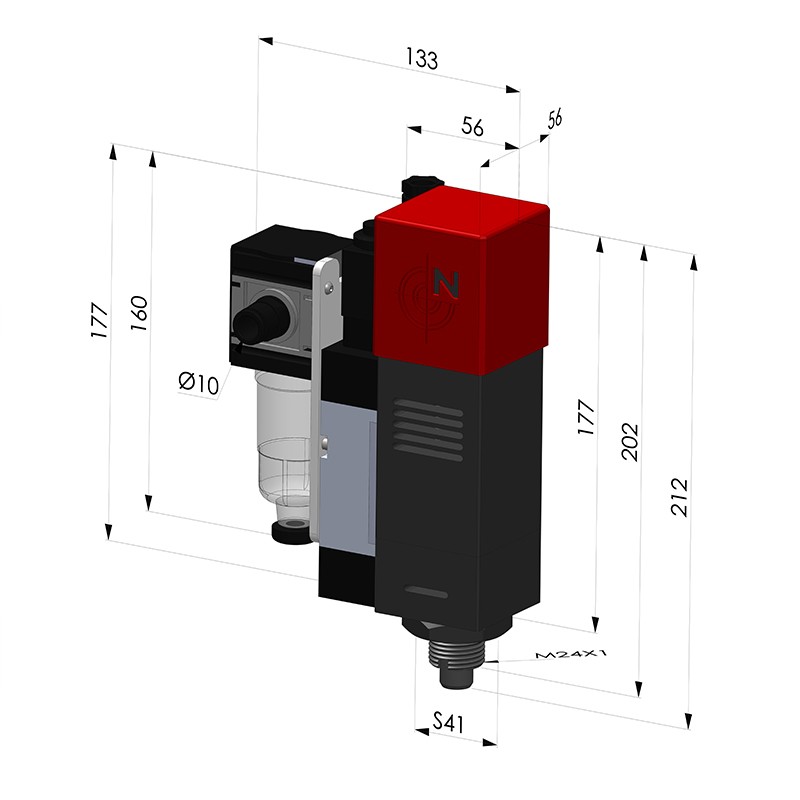

| Item number | Connection (GAZ) |

Generator | Cooling capacity | Consumed Air (L/min) |

Air flow at outlet (L/min) |

Cabinet size (Meters) |

Weight (Grams) |

Material | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (Kcal/H)** | (BTU/H) | 6 BARS | 7 BARS | 6 BARS | 7 BARS | ||||||

| CLIM-2 EL 500 | G1/4" | GEA 10R  |

95 | 376.99 | 381 | 430 | 115 | 152 | 0,5x0,6x0,2 | 1085 | Aluminium |

| CLIM-2 EL 900 | GEA 15R  |

135 | 535.72 | 400 | 495 | 152 | 170 | 0,8x0,6x0,2 | |||

| CLIM-2 EL 1500 | GEA 25R  |

440 | 1746.06 | 494 | 597 | 205 | 285 | 1,0x1,0x0,4 | |||

| CLIM-2 EL 2500 | GEA 35R  |

720 | 2857.19 | 635 | 786 | 340 | 375 | 1,8x1,8x0,6 | |||

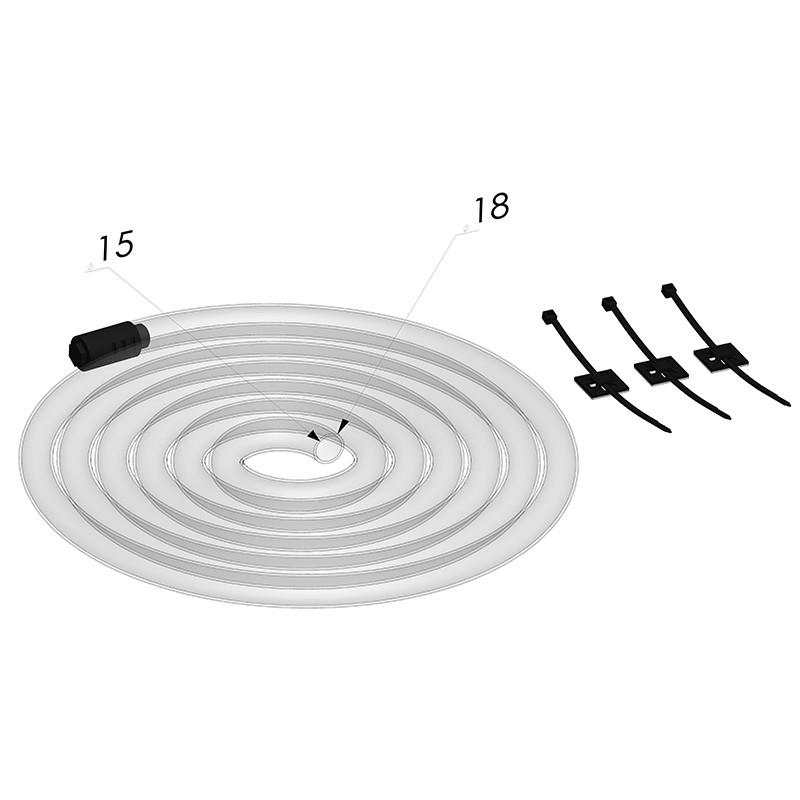

For optimal results, we recommend using an 8 mm inside diameter tube for CLIM-2 EL 500 and 900 items, and a 12 mm inside diameter tube for CLIM-2 EL 1500 and 2500 items..

** The kilocalorie is an energy unit, a kilocalorie (equals 1000cal) represents the quantity of energy needed to reduce the temperature of 1 °C inside 1000 liters of water.

USE

Novacom designs and develops, in France, vortex cabinet coolers for electrical cabinets.

In an industrial environment, electrical cabinets are often exposed to temperature rises, which can cause overheating of their internal components.

This can lead to malfunctions, or even equipment failures.

A Vortex cooler can help avoid these issues by regulating the temperature inside the cabinet. This air cooler will also slightly pressurize the electrical cabinet, which will prevent any risk of dust clogging.

RUNNING

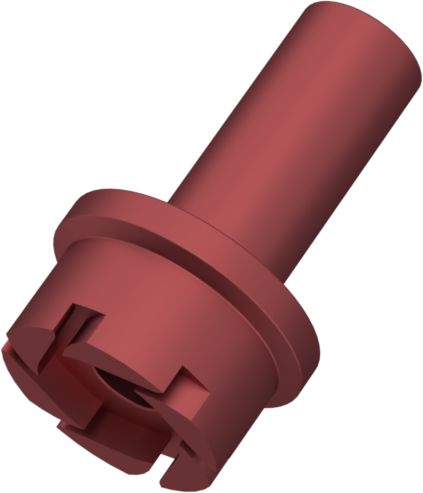

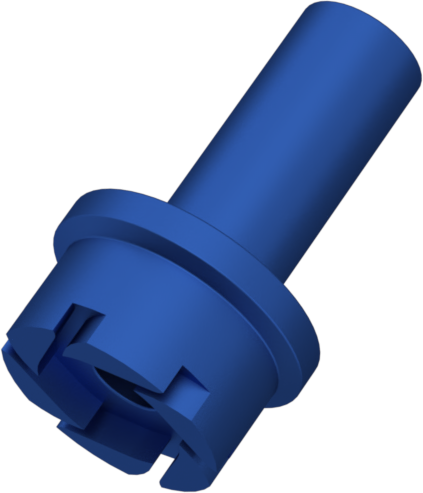

Made of stainless steel, they are composed of several components, such as vortex generators. The generators allow the temperature and airflow rate to be adjusted in the vortex tube.

Novacom offers 4 different Vortex generators, suited according to the size of the electrical cabinet. The incoming compressed air passes through the fixed cylindrical generator, which forces the air to whirl at high speed inside the tube. The air heats up strongly by rubbing the inner walls of the tube and escapes through the hot air outlet.

The throttling valve, located at the hot air outlet, physically prevents the air flow from escaping.

The air is then pushed back inward and is forced to make the reverse path through the center of the cyclone.

This flow runs at a slower speed, and the speed differential causes significant heat exchange. When the air flow escapes through the cold air outlet of the Vortex tube, it can reach a very low temperature, up to a delta of 40°C, compared to the temperature of the incoming compressed air flow.

SCHEMATIC DIAGRAM

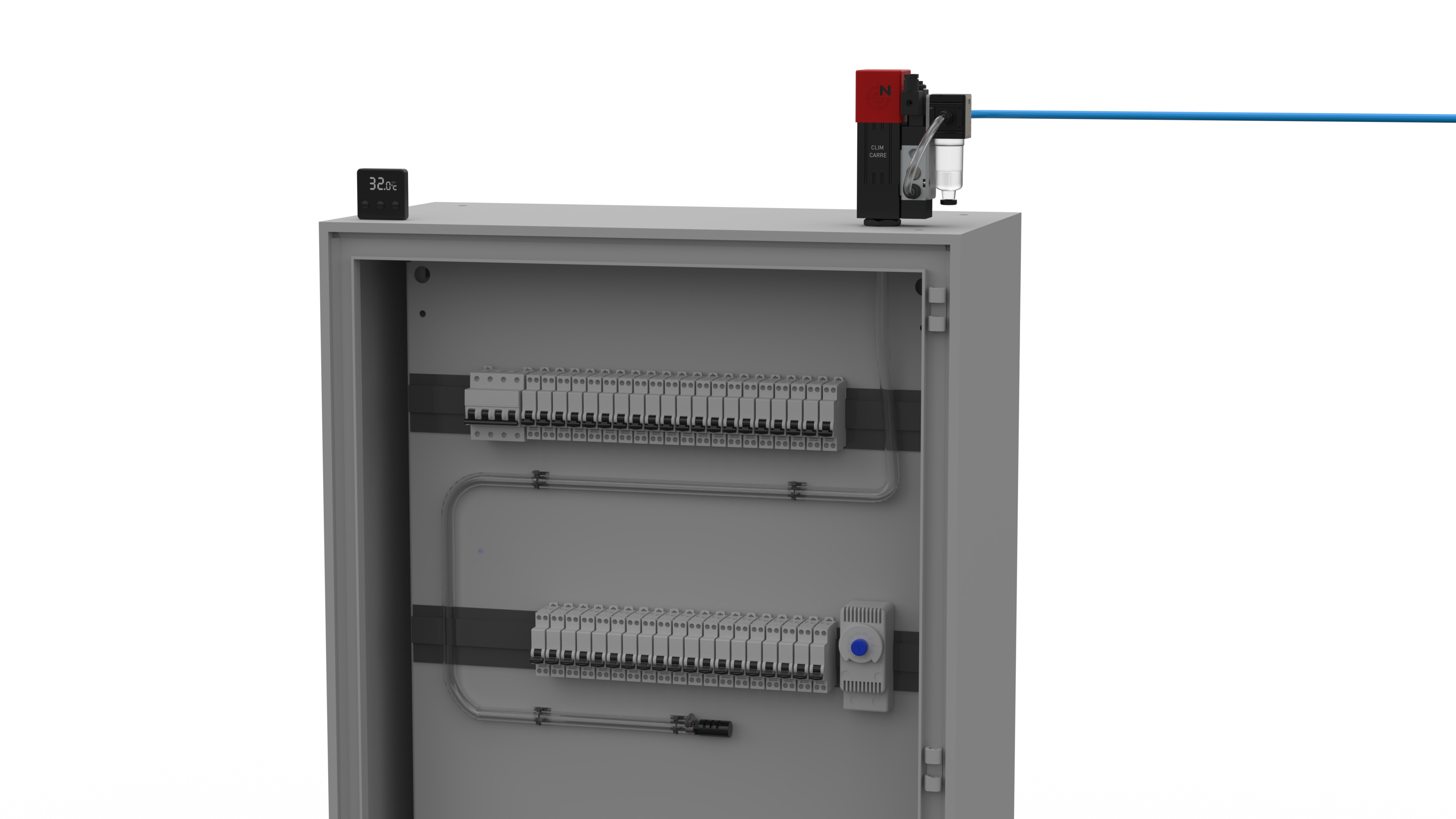

INSTALLATION

To install a Vortex cabinet cooler, start by drilling a 25mm diameter hole on the top of the cabinet. Then insert the device and tighten the locknut to ensure good stability and proper sealing.

Next, drill some holes in the cold air distribution pipe, prioritizing overheating areas. This will optimally cool the components most sensitive to heat.

Use cable ties to secure the cold air distribution pipe inside the electrical cabinet.

This ensures the pipe remains in place and does not interfere with other components.

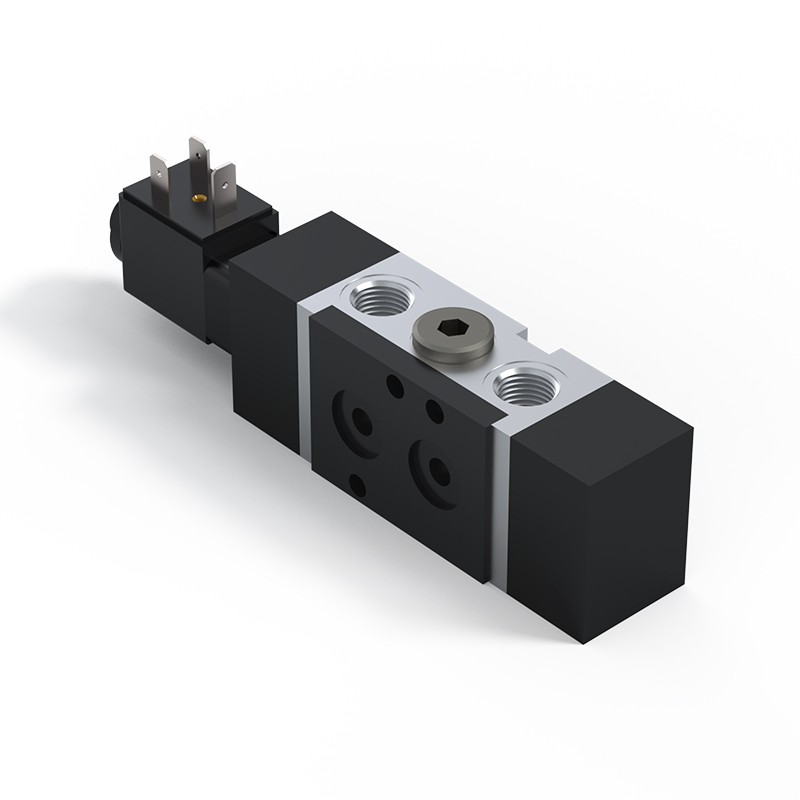

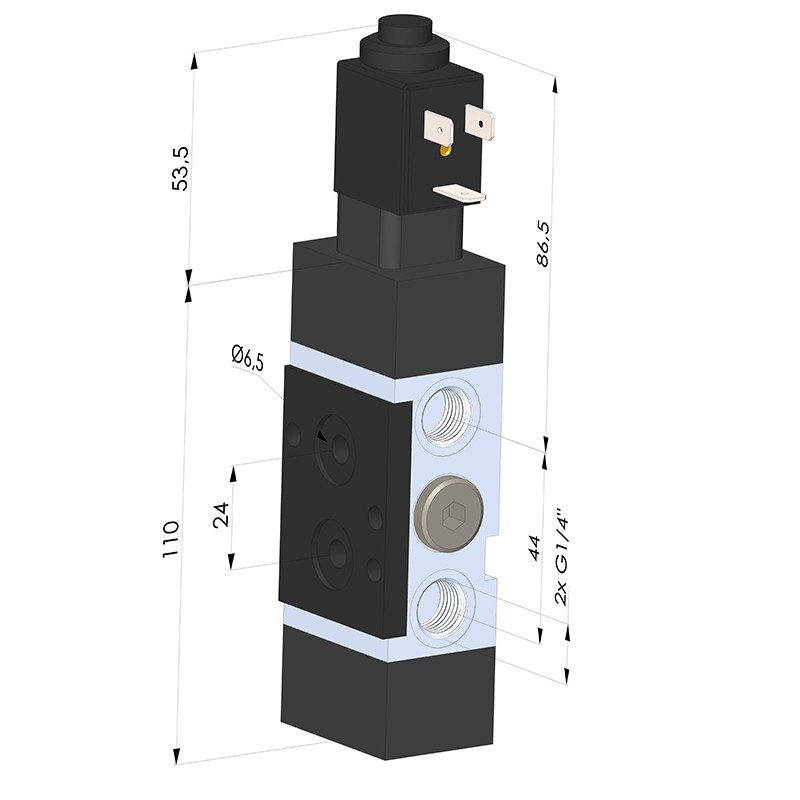

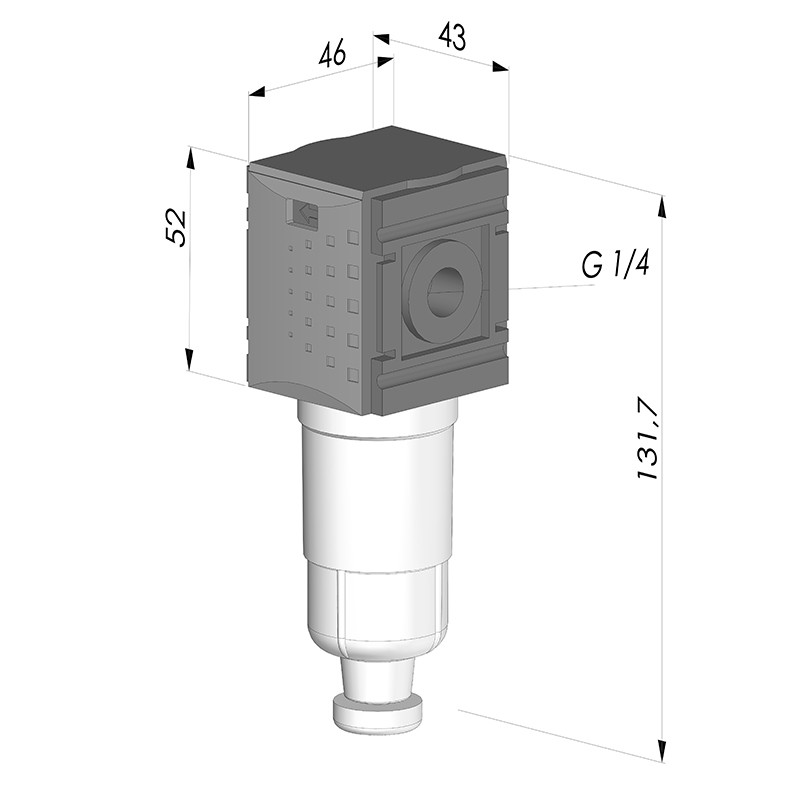

Then connect the Vortex cooler to a compressed air distribution network set at 7 bars. Install the filter regulator and the solenoid valve close to the air cooler to ensure the quality of the compressed air supply and a precise air flow control.

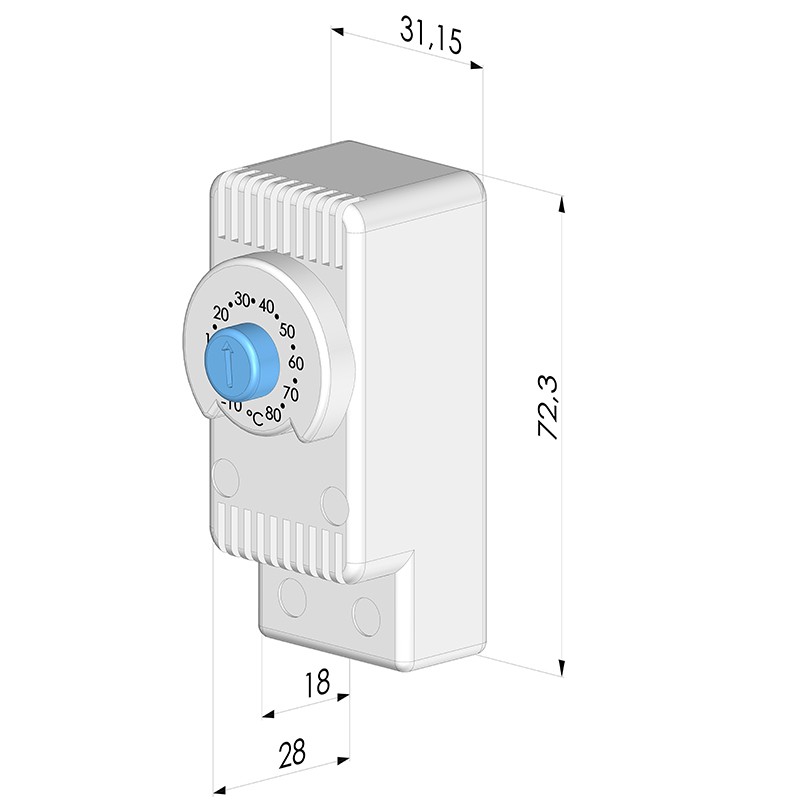

Finally, install the thermostat, which will control the solenoid valve, ensuring a constant and precise temperature. Connect the thermostat directly to the electrical panel and to the solenoid valve. Set the thermostat to the desired temperature and ensure that the cabinet is perfectly sealed.

This type of air cooler is designed for electrical cabinets with a maximum volume of about 2 cubic meters, depending on the chosen vortex generator. Therefore, they offer a solution suitable for a wide range of applications.

With your Novacom Vortex cabinet cooler, you are now ready to prevent overheating and ensure the longevity of your electrical equipment.

You might also like

Italian

Italian French

French