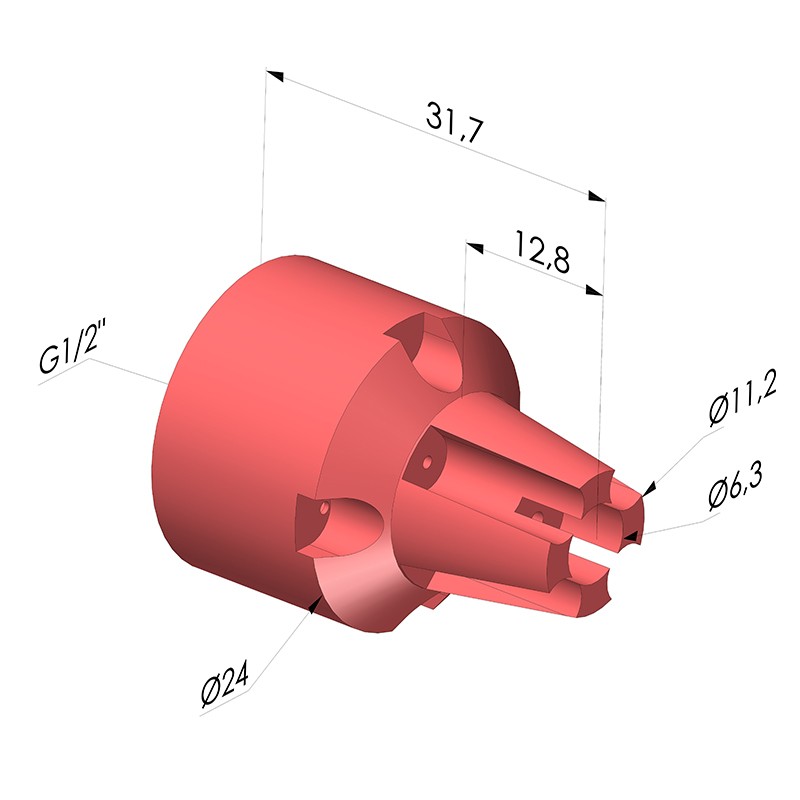

| Type | Round stream |

|---|---|

| Connector | G1/2" |

| BENEFITS OF USING A BS9 F12* AIR NOZZLE (Compared to a open pipe) |

Increase of blowing force (%) |

Noise reduction (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| Up to 92% |

Up to 26% |

|||||||

| BLOWING PERFORMANCE BS9 F12 NOZZLE* |

Pressure (bar) | Air Consumption (l/mn) | Blowing force (N) | Noise level (dB) | Amplified blowing (l/min) | |||

| 6 | 970 | at 150mm | at 450mm | 81 | 4720 | |||

| 12,1 | 10,5 | |||||||

| VS | ||||||||

| OPEN PIPE Ø12* |

Pressure (bar) | Air consumption (l/mn) | Noise level (dB) | Amplified blowing (l/mn) | ||||

| 6 | 4450 | 110 | 4450 | |||||

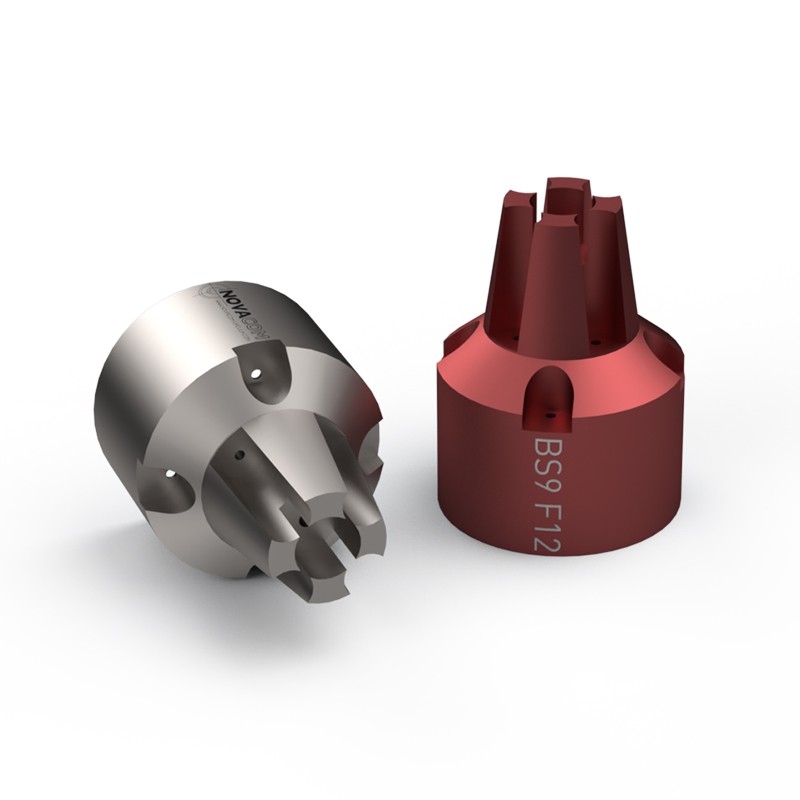

BS9 F12* NOZZLE FEATURES*

• Connection : Female G1/2" • Weight : Aluminium : 12g / Stainless steel 316 L : 28g

• Max. operating temperature : Aluminium : 150 °C / Stainless steel 316 L : 450°C • Max Pressure : 10 bars

* NOTE: The measurements in this data sheet have been obtained in a laboratory under strict control. The varying conditions of a real industrial environment and the instability of pressure from an industrial compressor can create different values than the ones obtained in a laboratory. Those data are provided for information purposes only.

To achieve the best performance from the air nozzle, we recommend using a compressed air supply tube with a minimum 12 mm inside diameter.

Italian

Italian French

French