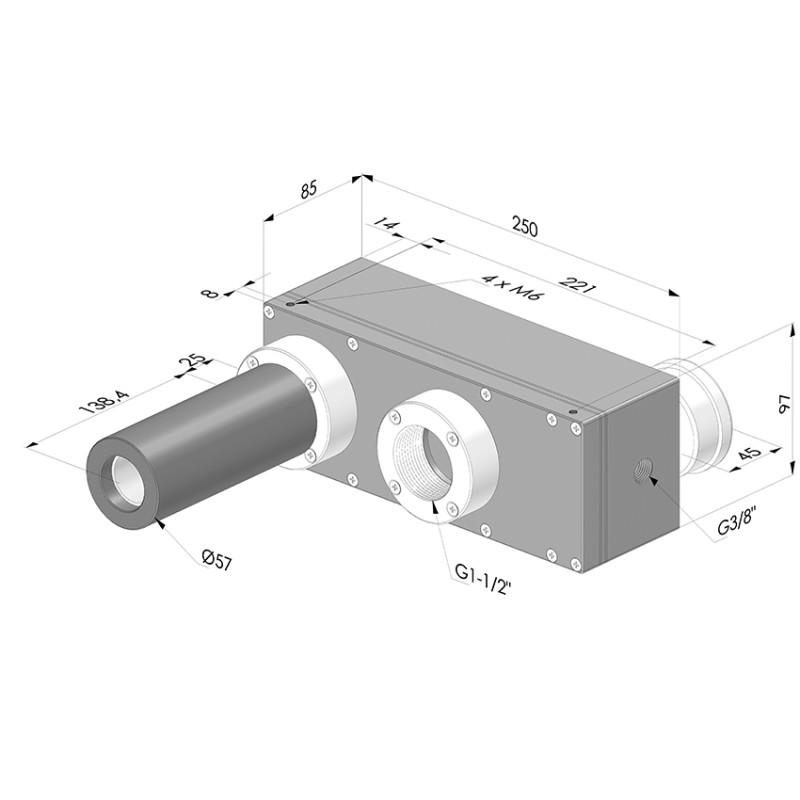

| Type | Multi Stage |

|---|---|

| Series | VME |

| Vacuum | 90% |

| Suction capacity | 3200 l/min at 6 bar |

Principle The multi-stage VME ejectors suck a large volume of air at start-up. They operate on the principle of the series mounted ejector. The ratio between the sucked air flow and the used air flow is excellent. For visual verification of the partial vacuum, a vacuum gauge is installed on the ejector. Advantages - Very large sucked air flow as soon as compressed air is applied - Low noise level - Energy savings - Excellent ratio between sucked air and used air Applications - Gripping porous products - Creating a vacuum for thermoforming - Short time to create a partial vacuum - High throughput Specifications of the VME 240 - Air sucked at 4 bar: 2400 Nl/min i.e. 40.00 l/sec or 144.00 m3/h - Vacuum at 4 bar (%): 70 - Air usage at 4 bar (Nl/min): 750 - Air sucked at 6 bar: 3200 Nl/min i.e. 53.33 l/sec or 192.00 m3/h - Vacuum at 6 bar (%): 90 - Air usage at 6 bar (Nl/min): 1050 - Weight (g): 3800 - Silencer model: SIL 112 Specifications - Compressed air: Filtered, not lubricated, pressure 2 to 6 bar - Temperature: -20 to 100°C - Material: Aluminium, silicone and neoprene gasket

Italian

Italian French

French