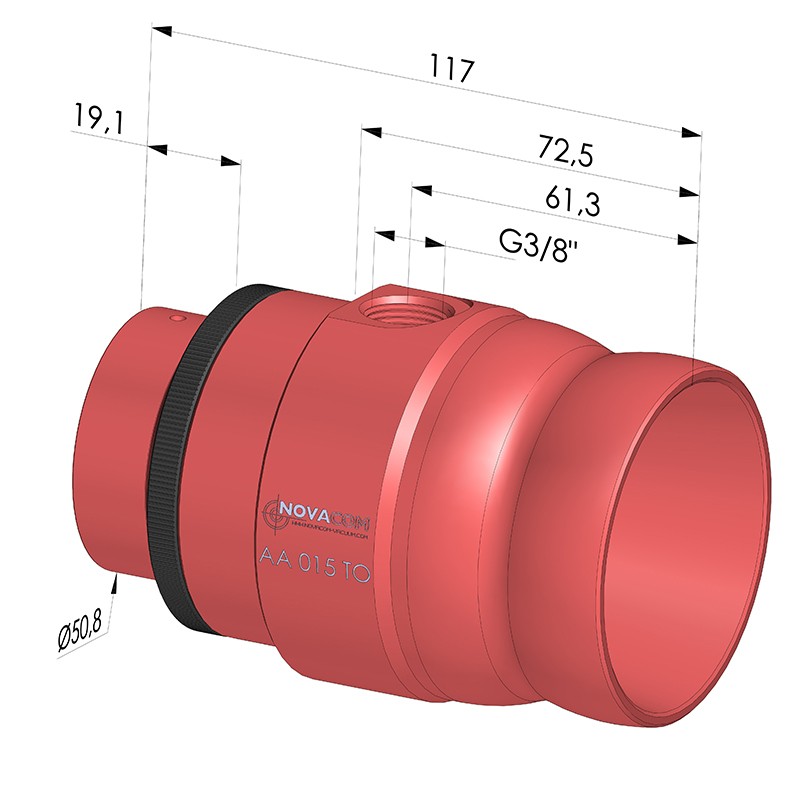

| Material | Anodised Aluminium |

|---|---|

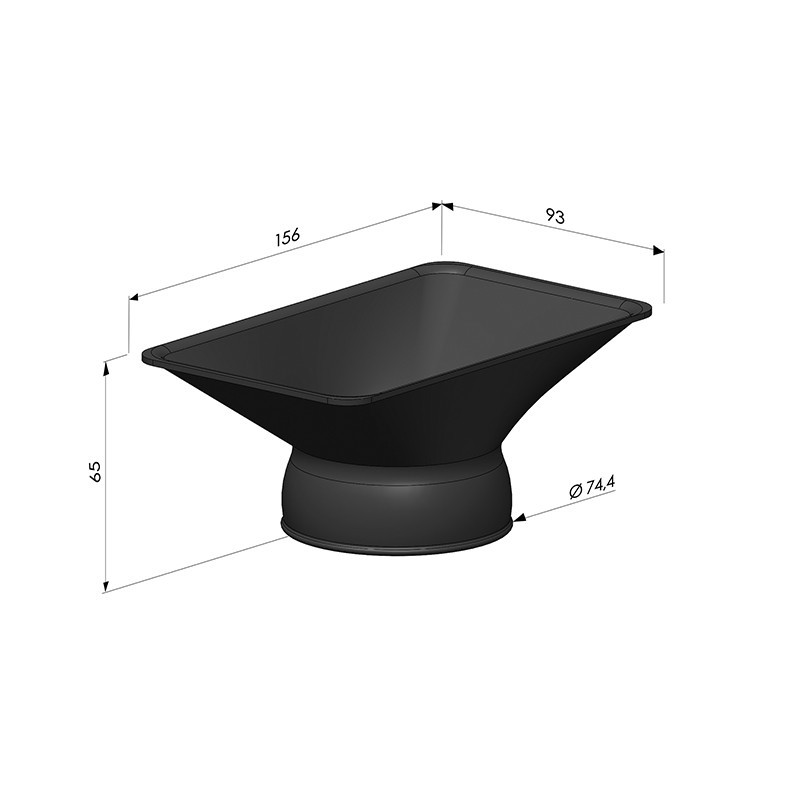

| Type | Amplifier nozzle |

| Height | 82.7 mm |

| Outer Diameter | 76.2 mm |

| Connector | G3/8" |

| Blowing | 14 169 l/min at 5.5 bar |

TECHNICAL INFORMATION

| BENEFITS OF USING AA 015 TO* AIR AMPLIFIER | Pressure (bar) | Air consumption (l/mn) | Noise Level (dB) | Aspirated surrounding air (l/mn) | Amplified blowing (l/mn) | |||

|---|---|---|---|---|---|---|---|---|

| 6 | 1400 | 87 | 3300 | 13960 | ||||

AA 015 TO* AIR AMPLIFIERS FEATURES*

• Connection : Female G3/8" • Inside ⌀: 41mm • Weight : Aluminium : 519g / Stainless steel 316 L : 1528g

• Max. operating temperature : Aluminium : 150 °C / Stainless steel 316 L : 450°C • Max Pressure : 10 bars

* NOTE: The measurements in this data sheet have been obtained in a laboratory under strict control. The varying conditions of a real industrial environment and the instability of pressure from an industrial compressor can create different values than the ones obtained in a laboratory. Those data are provided for information purposes only.

To achieve the best performance from the air amplifi ers, we recommend using a compressed air supply tube with a minimum 8 mm inside diameter.

The amplifi cated air value uses the Boyle-Mariotte law. The pressurized air has a less important volume than the expanded air and is translated by the formula: P1xV1=P2xV2

In our case V1= consummed air + aspirated air

You might also like